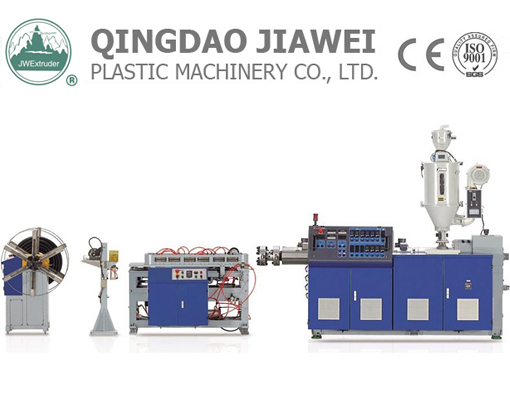

Depending on the type of raw material to be used, this extrusion system offers either signle or twin screw extruder as well as vacuum calibration table, extrusion die, cooling system, metering device and double station winding machine. It can continuously extruding various sizes of corrugated pipes.

Performance characteristics:

• The extruder

High speed single/twin screw extruder with channeled cylinder, high efficiency extrusion guaranteed.

• Corrugated shaping system and molds

Strong cooling Corrugated shaping system is installed within the extrusion system, provide high speed extrusion, size precision and stable quality;

High quality of mold alloy to make the molds, high hardness and toughness, abrasion resistance, and great heat dissipation;

Varity of shaping molds to choose from, uncommon shape can be specifically designed.

• Enlarging machine

Advanced on-line opening enlarging machine, pipes be enlarged during the extruding process.

• Control system

PLC control system, fully automatic.

Key Technical Parameters

| Model | Size Range

| Extruder Model

| Hall-off Speed

| Installed Power |

| DBG-10 | Φ6—10mm | SJ45/28 | 1—20m/min | 45kw |

| DBG-25 | Φ8—20mm | SJ45/28 | 1—15m/min | 50kw |

| DBG-63 | Φ16—90mm | SJ65/30 | 1—10m/min | 70kw |

| DBG-200 | Φ110—220mm | SJ90/30 | 1—5m/min | 88kw |

| DBG-300 | Φ160—300mm | SJ120/30 | 0.5—4m/min | 130kw |

The above specification is subject to change without prior notice