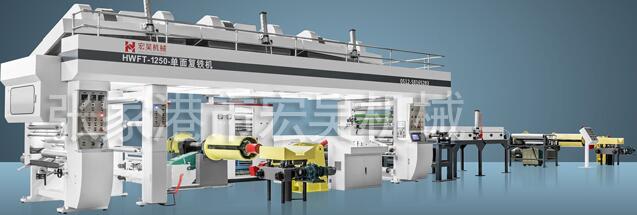

technical parameters and major configuration

Film unwinding unit

technical parameters

Single - station unwinding of the film used according to the independent frame, 5 kg of powder arrester control tension.

Gas expansion shaft, the axial length of the support 1050 mm

Place, 600 mm, the diameter of the roll?

Robinson, a tension control range 3 - 30 kg

tension precision:. + -. 0.25 kg & # xb7;

Juan material laterally - adjustable amount + 20 mm

coating unit

technical parameters

coating, a roll length of 1050 mm

, the applicator roller diameter 165 mm (100?)

coating roller 120? mm, and a nitrile rubber (Shore A) 70 o

gluing pressure of 350 kg & # xb7;

- drive 2.2 kW motor full - digital AC variable frequency control system

functional characteristics

/ applying manner as the anilox roller in a quantitative manner, the application roller as a unitary structure.

Pneumatic pressure and the pressure of the coating roller, pressure roller shaft is coated, rapid replacement of the two falling cylinder, the clutch is locked automatically.

Scraper device, three position adjusting structure.

Glue bucket is open from the backflow, up - down manual adjustment.

/ applying rollers are individually motor driven tension control precision is high.

feed rollers for bilaterally adjusting manner

/ applying, the overall rigidity of the design, there are fast replacing function

oven unit

technical parameters

The maximum temperature of 100 oC

8000 mm long in the box,

30 m / s wind speed,

An electrically heated 3 KW * 6 3 *

The nozzle 16

The feeding - end auxiliary oven and the cylinder, which is capable of being opened.

temperature control precision 1 oC

The maximum quantity of 1500 m3 / h

, fan power 1.5 kw x 3

functional characteristics

Twice, to save energy

gas - oven top, a decorative plate and threading operation platform

multiposition 回风路, Minister for Foreign Affairs, on the whole surface of the cyclone layout, get under the conditions laid down, the solvent is volatilized completely

Negative pressure design, the whole of the oven, hot air oven 不吹出

Fragmentation and shits, automatic thermostatic control, the solvent is volatilized completely

Huge, wind speed may create a low - temperature drying

Front exhaust initial volatilization of the solvent discharged secondary cycle,

the oven outlet, installing deviation rectifying device

composite unit

technical parameters

Composite roller 270, mm?

pressure, with cots? 160 mm EPDM of Shore (A) 75 - 70 o o

back - pressure roller,? 150 mm shall be chrome - plated steel roller

, the composite roll of the highest temperature of 240 oC

preheating roller 100 oC

Electric heating power kw, 9

7.5 kw motor - drive - digital controlling Anchuan frequency conversion control system

Composite pressure 2100 kw,

The tension setting, the range of from 3 to 30 kg

Functional characteristics

Separate drive and the tension closed loop control to ensure the quality of the composite film with constant - tension composite, finished flat

hot air drying, the tension of the tension sensor for pressure detection, a full closed - loop tension control stable system

precision, the surface temperature by external heating of the oil tank heating system that the roll temperature

pneumatic pressure and the clutch mechanism pressure adjustable pressure, the clutch quickly

Separate drives can be set to a smaller tension, avoiding the large tension in the elongated film oven

for non - contact temperature control, or precise temperature measurement control system

rewinding unit

technical parameters

gas expanded shaft supporting the roll length of 1100 mm

William received 600 mm, the diameter of the roll?

tension control, a range of 3 to 30 kg

Single - station receiver coil, the magnetic particle clutch 50 NM

Juan material laterally - adjustable amount + 20 mm

hydraulic unwinding unit

, the machine frame are welded by steel plates.

, four hydraulic diameter range and the entry of the 450 mm, and the entry of the arm length of 1100 mm 508 MM

Lawrence Place at the center of the roll height 1050 mm,

, and a magnetic particle brake tension KG 40

, the bottom part of the upper mounting a movable roller, the motorized movement of the screw, the adjusting range is 200 mm.

Four hydraulic cylinders, motor power 5.5KW

tin oven unit

Ironhide, preheat the oven, the cap is opened, the built - in quartz, chrome - plated rollers 5.

correcting unit

, oven outlet installed grid - control rectification device, uses a Hydro - Pneumatic Deviation

, cots? 200 * 1050 mm 2.

discharging roller unit S

, the rack is of welded steel plates, the base channel steel is welded, on everybodyall auxiliary steel plate

S. adopt the EPDM and the entry of the roll 400 * 1050 mm 2.

Double - cylinder, pressing, pressing 辊为 rubber roller and the entry of the 150 mm, 100 mm 6NF 辊为?

Magnetic powder brake, 20 kilos.

hydraulic winder

The frame welded by steel plates, the machine is processed

, and the entry of the hydraulic diameter in the range of 450 mm, and the entry of the arm length 508 MM MM 1100.

Lawrence Place at the center of the roll height 1050 mm

Vol. 15, for the motor, inverter Yasukawa 15 kw motor

reducer, the center distance 750 mm, the ratio of 31.5