Major model: XLB-01Y/XLB-03Y/XLB-04YF/XLB-06Y

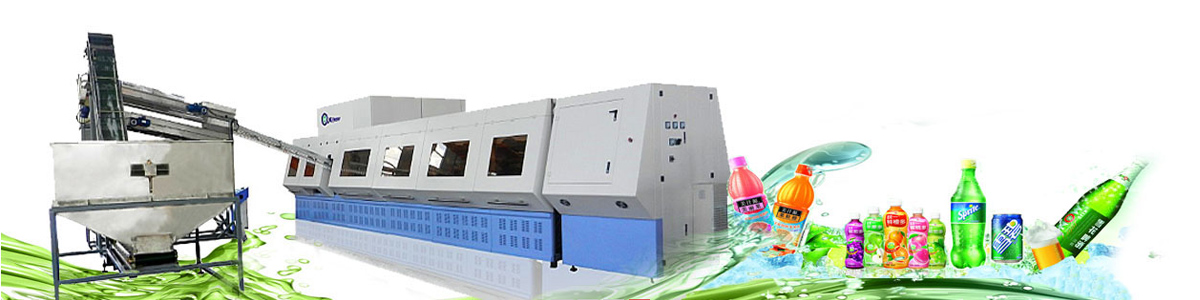

This model uses electric servo system, specially for large capacity bottles of customers’ design, especially for 3-5L edible oil bottle, drinking water and beverages, the machine has the advantages of low energy consumption, high accuracy, good stability, saving area and etc.

Overview:

1、Mold base: This machine’s mold base adopts pressurized symmetry structural form of four formwork’s back side, and has the advantages of fast motion, stability and reliability, small mechanical vibration. Opening and closing mold’s power module adopts sigle power rotary connecting rod clamping mechanism which is researched and developed independently by Xilinear.

2、Heating mechanism :The heating light box adopts automatic mutual feedback and closed loop adjustment system, which can automatically in proportion output constant power and can be exempted from voltage fluctuations, greatly improved the stability of the heating system. The operating power of each layer can be adjusted independently, simply set up the corresponding adjustment table. Operation is simple. Minimum power amplitude modulation is only five thousandths of the maximum power, which can be very good to achieve fine temperature regulation at different heights of the bottle preform to ensure bottle blowing process requirements.

Characteristic:

Technical features:

1、 Features: full servo control system, the structure is stable and reliable, high-speed and smooth.

2 、Rotary loading preform mechanism, stable and reliable. Can adapt to the requirements of different sizes of bottle preforms.

3 、Servo transmission system, high positioning accuracy, fast and stable, good reliability, no need of gas supply, the maintenance cost is low, servo motor controls stretching rod to stretch bottle preform. The advantage: it can make segmented stretch, firstly make preform positioning, ensure preform verticality when stretching, then make the second stretch. Ensure the uniformity and consistency of each preform when stretching. Fast tension, position precision.

4 、Adopted fission structure of clamp head and clamp body, can quickly change different clamp head. The variable speed clamp rotation device can adjust the rotation speed of the clamp at any time, and ensure the uniformity of preform heating.

5、 Adopted linear structural design. Can easily adjust the height of the tube and the distance between preforms, to reach the best effect of the preform heating. Quick and simple replacement of lamp tube. Adopted the method of continuous temperature heating to ensure heating temperature uniformity of each preform. Preform spacing is small, can effectively save energy. There is a bottle screw protective plate to prevent heat distortion of bottle screw during heating process.

6、 First-class air supply control system, ensuring the uniform and quick reaction of blowing air flow, providing quality and uniformity of product.

7、 Advanced high-pressure lock blowing mechanism, stable and reliable operation, small vibration, which is suitable for different bottle type requirements. Good blowing neutral, the mold clamping line is small, the cam bottom die is designed with the dynamic design, and the synchronization is high.

Specification:

After-sale service:

After-sales service Service concept:

emphasis on commitment and trustworthy, excellent technology, high-quality and high-efficient, common development, once input and lifelong maintenance. Professional after-sales service engineering and technical personnel, good brand reputation, customer satisfaction as the lifeblood.

1、24-hour hotline service launched.

2、Fast response: ensure arrive at the scene after receving customer maintenance report in 24 hours (in province), 48 hours (outside province).

3、Professional technical training.