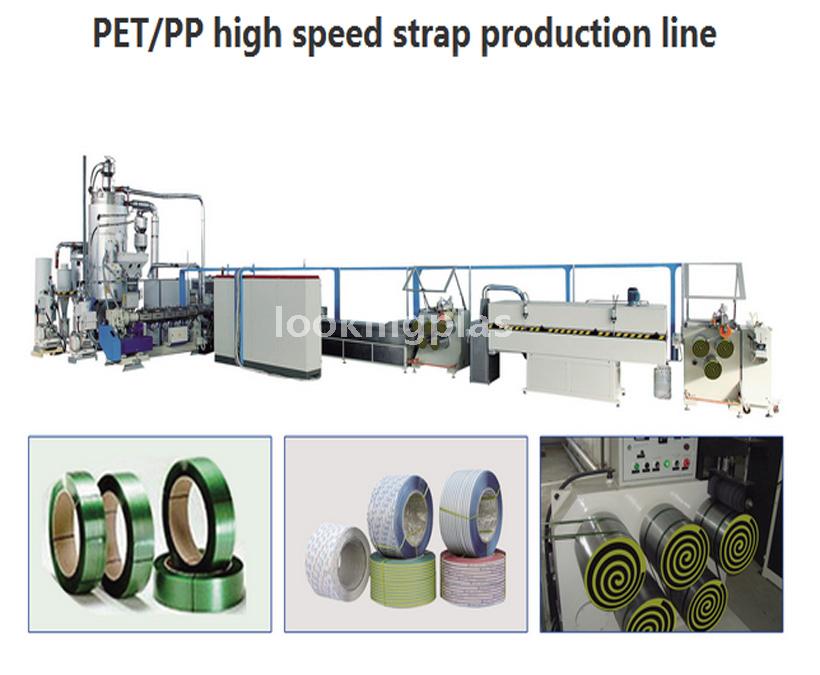

PET/PP high speed strap production line

PET/PP high speed strap production line, PET strap extrusion line, PP strap extrusion line

Product use:

Strap (PP,PET) into PP strap (also known as polypropylene packing tape) and PET strap (also known as plastic packing tape), respectively, using polypropylene and PET polyester raw material production, respectively, for the severity of different objects packaging needs.

Equipment production processes:

PP/PET strap production process: mixing—drying— Heating and melting—Extruded into water to form a band germ—Heating stretch forming—Embossing—Heating and cooling—Winding—packing—Storage.

Equipment Advantage:

1.Can produce a two line speed 120-160 m / min, capacity 160-200kg / h;

2.Can produce a four line speed 100-150 m / min, capacity 240-400kg / h;

The feature of GPM strap production line:

The efficient extrusion host, metering pumps, a two or a four precision molds, lengthen the cooling water tank, oven, traction embossing unit, dual configuration tape unit, automatic temperature control cabinet split composition, adapted to all levels of regeneration plastic particles, with and without the production of sandwich sandwich belt. The equipment has the following features:

1.can produce a variety of handmade belt, machine belt and exit zone;

2.to reduce operating workers, each production line from the original class 3, reduced to 1-2 people per class;

3.plastic and strong, forming a stable and high yield;

4.Energy saving, energy consumption is 20-30% lower than similar devices, greatly improving economic efficiency;