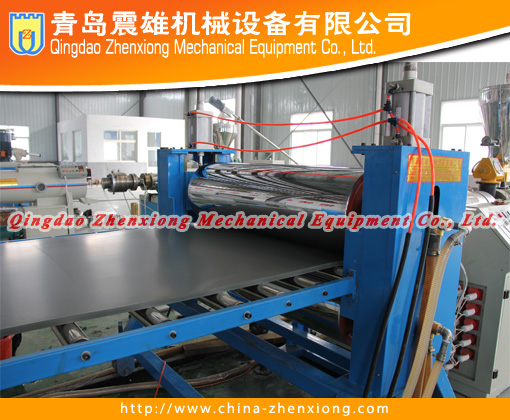

Plastic pallets for brick block making machine, Brick pallet production line

PVC Brick pallet production line

The lines have the advantages of well-planned layout, compact in structure, fine in performance such as homogenous plasticization, high output and long service life. The screws and barrels are made of special alloy and the structure is optimized. Exchanging screen rapidly about 1.5 seconds every times, the screen changer unit don't need the downtime. The cutting unit can guarantee the precise measurements through the adjustment of length and width, The lines are suit for PP, PE, PC, PS, ABS, PVC, PMMA, PET, HIPS etc.

Extruder:Screw of special design, advanced temperature control system to ensure good plasticization and the high yield and stability of plastic extrusion.

Changer: the selection of hydraulic quick changer device quickly and efficiently; duplex and special sealing structure to ensure the stable operation of changer.

Mould: mould adopt the quality alloy steel with a high activity of the throttling device, material flow uniform pressure distribution in the die; the differential regulation of the upper and lower die to ensure that the upper and lower wall thickness uniformity.

Haul off machine: Haul off machine use the large power, large reduction ratio, multi-roller excellent low speed performance, traction can simultaneously and evenly pull the plate from the vacuum shaping Taichung. The second haul off machine to handle stress. Equip with a side cutting device, to ensure that the plate width and plate edge quality.