Description

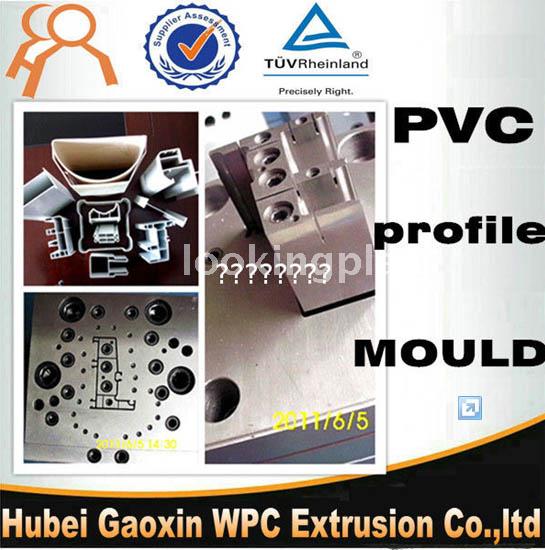

Most accurate plastic profile extruder machinery mould for PVC window profile made in China

1,One set of mould including:Dies head+heater plates+Calibrators+water tank+Spares

2.Air cooling style

3,This type of mould is mostly used with extruder lines to make the PVC Product

4,Custom-made according to your profile drawings or samples

.jpg)

The configurations of PVC profile Extrusion Tools and their functions

Configurationof Mould | Functions | Types |

Dies head | Produce continuous,stable,homogeneous profile | Divided into four standards based on different appearances: D1602,D1802,D2002,D3002 |

Calibrators | Cool down and form the profile, the smaller the resistance is ,the better | Divided into four standards based on different widths: C1402,C1702,C2002,C3002.The quantity of calibrator parts are decided by profile, and extrusion speed. |

Water tank | Cool down the profile further | Divided into three kinds: organic glass, stainless steel, pp board. They have wonderful tightness, brief frame, easily be processed. |

The classification of the moulds

| 1 | Mould for WPC Hollow Decking |  |

| 2 | Mould for WPC Solid Decking |  |

| 3 | Mould for WPC keel |

|

| 4 | Mould for WPC Pillar/Column |  |

| 5 | Mould for WPC Handrail/Railing |  |

| 6 | Mould for PE-WPC Wall Cladding |  |

| 7 | Mould for WPC Side Covers |  |

| 8 | Mould for WPC CO-Extrusion profile |  |

| 9 | Mould for PVC-WPC Door Panel |  |

| 10 | Mould for PVC profile |  |

| 11 | Mould for PVC-WPC Wall Cladding |  |

Our Services

HIGH QUALITY AFTER-SALES SERVICE

1,Over the past decade,we always provide customers with perfect service.

2,Our technicist will test each mould before they leave the factory.

3,We could give the whole support for customer in raw material formula,selection of extruder machine,mould technique and operation training on the spot.

4,We also can supply top-quality moulds and resonable price depends on customers requests(pictures or CAD drawing or samples).We also provide OEM service

.jpg)