1. MTS50 Twin screw extruder technical data:

MTS | 50 |

Diameter of screw[mm] | 51 |

Output torque[Nm] | 415 |

Main motor power[kW] | 45 / 55 |

Max. screw speed[rpm] | 600 |

Throughput[kg/h] | 130-250 |

2. Screw elements:

Adopts flexible modular design, which can be adjusted accordance with processing technology to suit for variety materials. Screw materials is high speed tool steel (W6Mo5Cr4V2), which is via notarizing treatment to increase abrasion performance with the hardness of HRC58-60;

3. Screw Shafts:

Adopts 40CrNiMoA material. Forging blank with hardening and tempering treatment after rough machining, and distressing treatment after finish machining, to reduce stress deformation and improve screw transmission stability, avoid interference with barrels and extend the life time of screw and screw barrels;

4. Screw barrel:

Adopt Bi-metallic (α101) with liner inside to improve abrasion resistant and enhance the lifetime, HRC60-62.

5. Volumetric Feeding unit:

Volumetric feeder is equipped with single screw, twin screw, hollow screw, forced-feeding etc, enhance to suit for different types of raw materials.

6. Reducing and distributing gearbox:

Gear box combine reduction and torque distribution function, using three-axis parallel design. Gear adopts the high quality alloy material; manufacturing process is according to the highest ME-grade control under the latest international standard ISO6336-1996, manufacturing precision as per ISO1328-1995 cylindrical gears precision. Gear adopt carburizing quench to make the gear-tooth surface harder. Adopting special software for gear grinding to produce the gear profile, ensure balance load for gear-tooth, high strength, low noise, and low vibration. Through various improvements, MTS gearbox’s carrying capacity and power allocation increase greatly, comprehensive leading same classification equipment.

The gearbox features as below:

• Multiple optimization of gear box structure based on the calculation,

• Special optimization of gear parameter in twin-screw force analysis,

• Adopts outer lubrication unit, convenient in maintenance,

• Adopts domestic advanced Plate-Fin heat exchanger,

• Adopts imported brand bearing as NSK, INNA, SKF etc.,

The gearbox consists of:

• Involutes gear teeth couplings between the output shafts and screw shafts

• Integrated thrust bearing assembly

• Lube oil lubrication system for bearings and gear meshing.

• Bottom part of casing designed as oil sump.

7. Electrical control sys.:

• Various controlling sys. for customer, such as SIEMENS PLC or normal metering control;

• Main motor's control by ABB inverter;

• Low voltage electrical component adopts LG or Schneider product;

• Set-up interlock protection and check point;

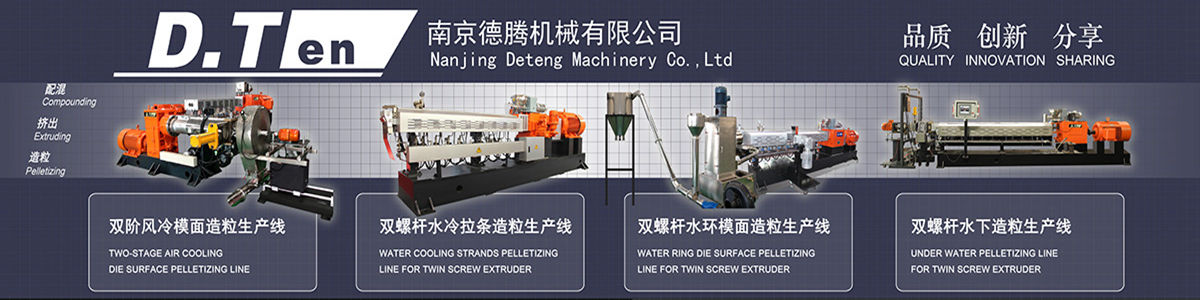

8. Pelletizing units:

Various types of pelletizing, such as water-cooling strand, air-cooling die face pelletizing, water-ring die face pelletizing, under water pelletizing, etc.

9. Service:

9.1. Before-sale:

• Introduce products in detail • Recommend suitable solution • Offer test

9.2. During manufacturing:

• Provide layout and engineering conditions • Offer screw profile

• Inform the project processing status • Order handling

9.3. After-sale:

• Provide installation, commissioning and training • Offer spare parts

• Provide necessary technical support and update information.