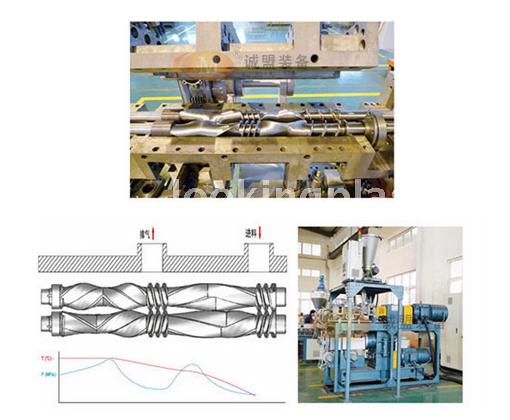

Two stage design, the first stage is double-rotor continuous mixer, used for plasticizing, kneading and mixing; The second stage is the single screw extruder or melt pump, used for cooling , pressure building and extrusion.

·According the stretch mixing design, this system has the characteristics of low shear, low energy consumption by folding, pressing, and kneading.And it will achieve more excellent dispersion mixing effect in low temperature condition.

·According the special pressure control system, it can be good controlled the residence time of material, filling rate, degree of mixing ratio and power consumption.

·The good design of many types rotors, the flexible adjustment, it is very good to meet the requirements of different materials and process

·Compared to twin screw extruder, it has the large effective volume, more flexible for material size.

·Split barrel design, easy open for cleaning and changing screw design

Typical applications:

Used for many kinds of high filling mixing modification operations; high concentration of carbon black masterbatch, color masterbatch, filler masterbatch and special materials, masterbatch, flame retardant masterbatch, shielding material, elastomer and rubber and etc.;