Overseas service available PVC 16-50mm two cavity pipe making machine

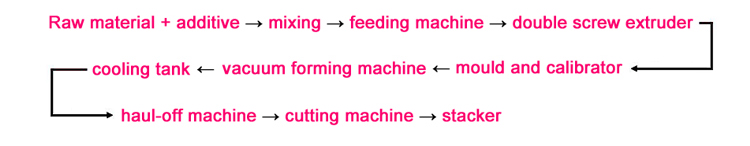

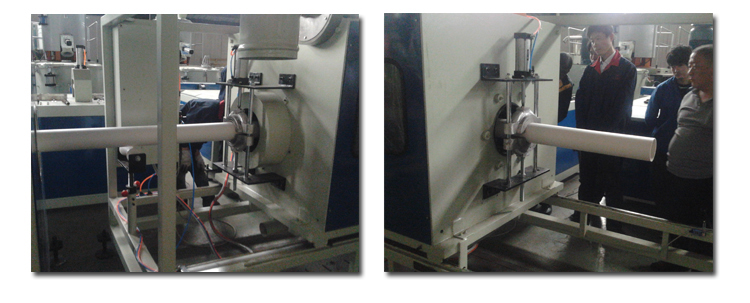

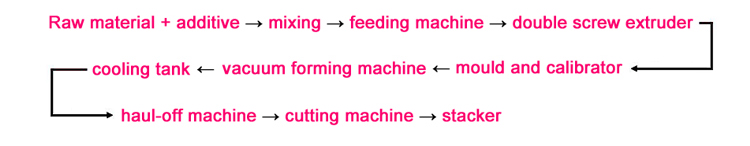

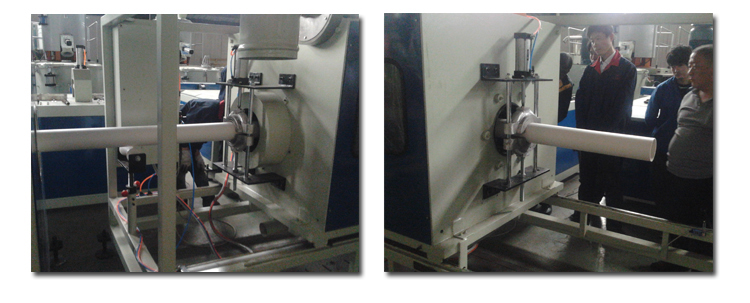

The one mould with two or four cavities PVC pipe extrusion line means one mould can produce two or four pipes.Under the conditions of ensuring the products' quality, this method can not only reduce the cost of equipment, plant and production, but also it can provide high output, and reduce the production time.

Main features:

1 Pipe diameter: 16-32,16-50mm.

2 Installed power: about 70kw.

3 Capacity: the two cavity pipe production line in a second tube production line product quality under the premise, the capacity is increased 80%.

4 Noise: The voice of production line is very low after starting up.

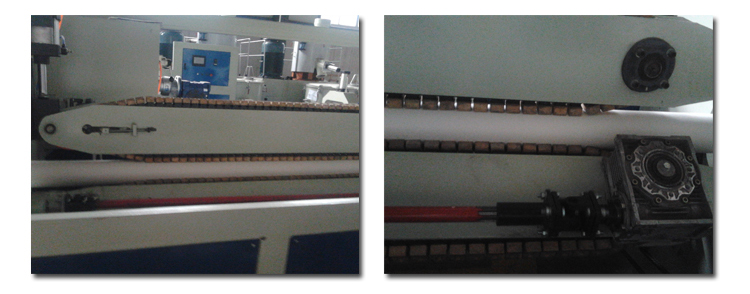

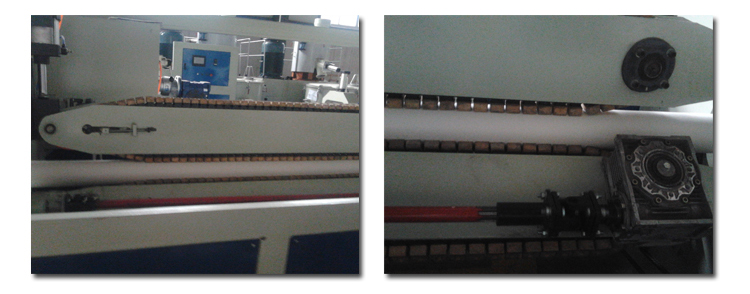

5 Dust pollution:There's no dust pollution, because the cutting part of the two or four cavities pipe production line is non chip cutting, and automatic driving cylinder.

Model | PVCG-32 | PVCG-50 | PVCG-160 | PVCG-250 | PVCG-315 | PVCG-400 |

Extruder | SJSZ65/132 | SJSZ51/105 | SJSZ65/132 | SJSZ65/132 | SJSZ80/156 | SJSZ80/156 |

Pipe size(mm) | 16-32 | 16-50 | 50-160 | 75- 250 | 110-315 | 200-400 |

Vacuum calibration tank length(mm) | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 |

Traction speed(m/s) | 0.6-8 | 0.6-6 | 0.5-5 | 0.4-4 | 0.3-3 | 0.2-2.5 |

Installed power(kw) | 80 | 67 | 85 | 95 | 125 | 135 |

Length of line(mm) | 17000 | 17000 | 18000 | 20000 | 20500 | 28000 |