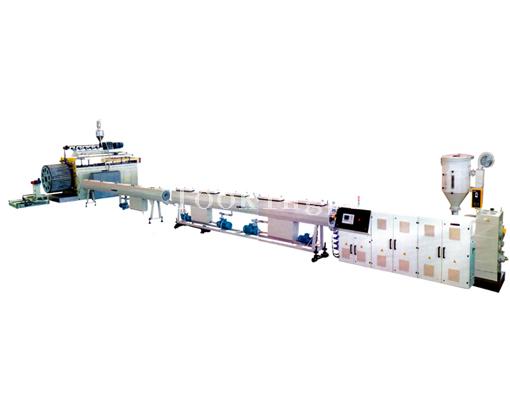

Largediamter Hollow-Wall Winding Pipe Extrusion Line

At present, the sewage and drainage systems in China still use the cement pipes. However, due ti its instade chemical property and loose connection. it has become the principle cause for envirorment pollution. On the other hand, the cast iron pepes cant't be used any more for the disadvantages. such as the inconvenient construction and expensive cost. In recent years, the plastic pepes become successful substitute to the cement pipes. Especially the newly developed spiral large diameter plastic pipes have been drawn great attention and have become the substitute products for cement pipes and cast iron pipes. All these shows that the twisted diameter plastic pipes have a great market potentiality.

● It has advanced technique and distinct technological design.

● The main extruder has adopted the high efficient single screw extruder. The optimized screw has used the German technique which enables it to guarantee high speed and high quality extrusion. It has employed the multiple handprece. two extruders charging and screw rotating formation. Its delicately and unique design guarantees the high quality of its product. The advanced PLC computerized control system makes it easy to operate and guarantees stable and reliiable performance.

● Connected with spcial filltings.

Main Technical Parameter:

| Model | Extruder | Pipe Range(mm) | Max Output Capcity(kg/h) | Total Power(kw) |

| Model | Motor Power | ID(min) | OD(max) |

| ZKCR800 | SJ65×30 | 45 | 200 | 800 | 200 | 150 |

| SJ45×30 | 15 |

| ZKCR1200 | SJ60×33 | 75 | 400 | 1200 | 350 | 210 |

| SJ45×33 | 30 |

| ZKCR1800 | SJ75×33 | 90 | 800 | 1800 | 450 | 320 |

| SJ65×30 | 45 |

| ZKCR2600 | SJ90×33 | 15 | 1600 | 2600 | 600 | 400 |

| SJ60×33 | 75 |

| ZKCR3200 | SJ120×33 | 250 | 200 | 3200 | 750 | 550 |

| SJ75×33 | 90 |

Machiney external appearance and technical parameter if needs development, please exuse us for without another notice,detailed parameters can make changed according to customers demand