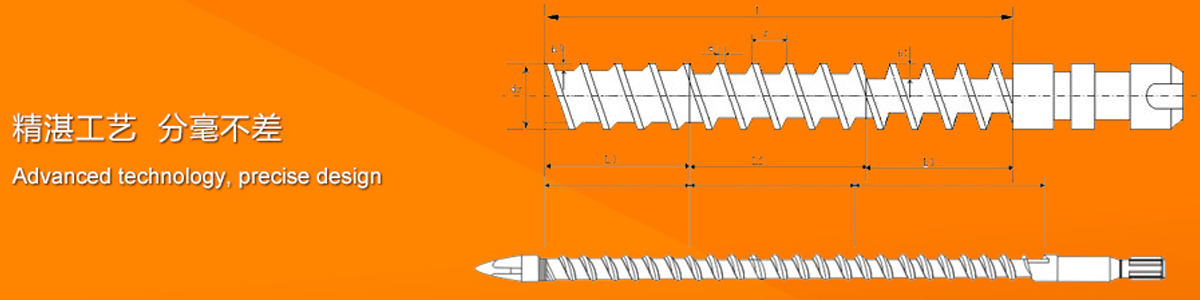

38D High Capacity Screw Barrel compare with classical 33D:

1.Average output increase 30-35%

2.Ratio of performance to cost increase 25-30%

3.38D longer screw make plasticizing capacity increasing distinctly

4.Screw with new concept of barrier, shearing and mixing makes melt temperature lower and melt heat uniformity increasing obviously

5.New screw make colour masterbach process much easier

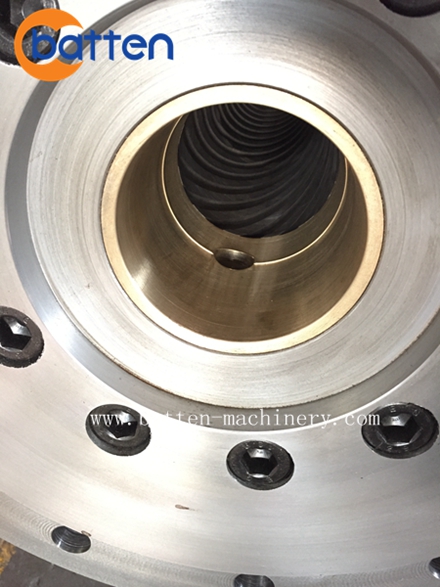

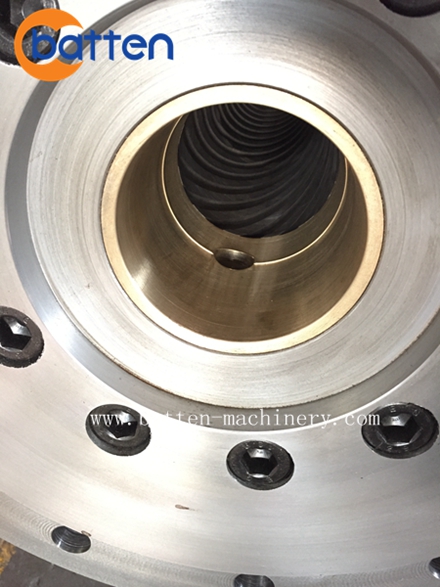

6.Innovation design of grooved bush with cooling

---high effiency of consant conveying

---plasticizing performance is not related to back pressure

---high output and low screw speed

---low friction loss

---low consumption of cooling water

7.High output

| Screw size (mm/LD) | Motor (KW) | Max Output (kg/h) |

| 60/38 | 110 | 460 |

| 75/38 | 160 | 600 |

| 90/38 | 250 | 1050 |

| 120/38 | 355 | 1300 |

Detailed photos: