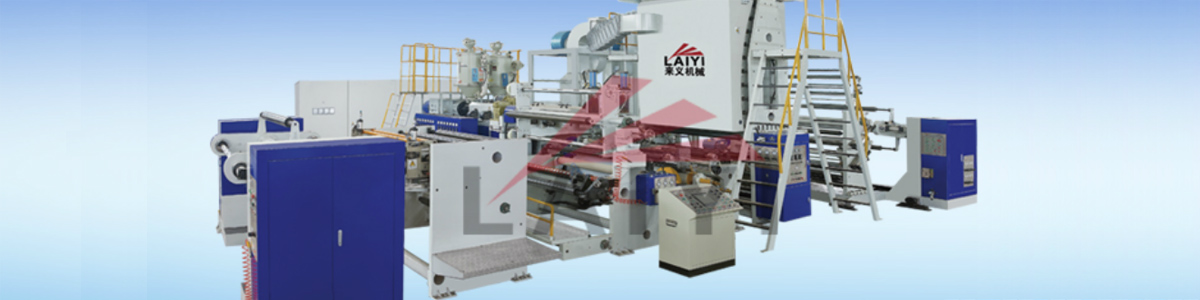

Single Side Paper Cup Extrusion Lamination Machine

1.Application:

For producing Single Side PE Coated Paper Cup Paper,Paper Bowl Paper,Instant Noddle Bowl Paper etc.

2.Feature:

(1)PLC Concentrated Control,Human-Machine Interface,Full Automatic Constant tension Control,New shaft

pre-speed start to realize large diameter high speed roll exchange,material cutting and connecting.

(2)Main machine adopts Electric lifting,easy to adjust mould air gap height.

(3)Mould head: High precision original imported from Taiwan,USA,Italy.

(4)Suitable for double side matt lamination for disposable paper cup,paper bowl,mirror lamination in high

efficiency,low cost and high speed.

3.Main technical parameters

Valid Coating Width | 1000mm | 1200mm | 1300mm |

Roller Width | 1150mm | 1350mm | 1450mm |

Machine Speed | 220m/min |

Extruder | LD-100 or LD-110,Automatic lifting Extruder |

Extruder Power | 55-75kw |

Extruder Capacity | 250kg/h or 300kg/h |

Used Resin | LDPE,LLDPE,PP etc. |

Coating Thickness | 8-45um |

Coating Average | ≤±5% |

Max.Unwind Diameter | 1600mm |

Max.Rewind Diameter | 1600mm |

Tension Control | Automatic Constant Swing Roller Closed Loop Tension Control for Unwinder and Rewinder |

Control Method | Human-Machine Interface,Extrusion thickness is automatically precision calculated by computer,whole machine linkage control |

Inverter | Imported AC Digital Vector Control Inverter |

Machine Dimension(L*W*H) | 18m*9.5-11m*3.8m |

4. Detailed Machine Photos:

This machine is for producing 1.7m Single Side PE Coated Cup Paper, Suitable Unwind and Rewind Diameter 1.2m, Cutting and connecting new roll without decrease the speed.Japan Sumitomo T-die, quite steady during producing. Sherman Corona, sufficent corona treatment. Middle Cutting Function, cut 1.7m paper to Two 850mm equal rolls, save the slitting cost and save time.

Unwinder

Extruder

Extrusion Laminating Unit

Sherman Corona

Ege Cutting

Middle Cutting

Rewinder