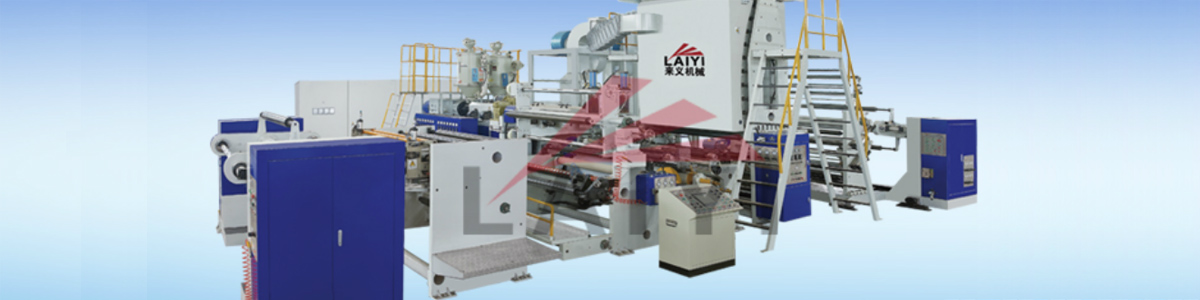

Automatic Double Side Paper Cup Paper Extrusion Lamination Machine

1.Application:

For producing double sides PE coated Paper Cup Paper,Paper Bowl Paper,Instant Noddle Bowl Paper.

2.Feature:

(1)PLC Concentrated Control,Human-Machine Interface,Full Automatic Constant tension Control,New shaft

pre-speed start to realize large diameter high speed roll exchange,material cutting and connecting.

(2)Main machine adopts Electric lifting,easy to adjust mould air gap height.

(3)Mould head: High precision original imported from USA,Japan,Taiwan,Zhejiang Jingcheng.

(4)Suitable for double side matt lamination for disposable paper cup,paper bowl,mirror lamination in high

efficiency,low cost and high speed.

3.Craft:

Unwinder-Corona-Matt Surface PE Lamination-Corona-Shining Surface PE Lamination-Cooling-Rewinder

4.Main technical parameters

Valid Coating Width | 1000mm | 1200mm | 1300mm | 1600mm |

Roller Width | 1150mm | 1350mm | 1450mm | 1750mm |

Machine Speed | 220m/min |

Extruder | LD-90 or LD-110,Automatic lifting Extruder |

Extruder Power | 37-75kw |

Extruder Capacity | 180kg/h or 300kg/h |

Used Resin | LDPE,LLDPE,PP,EVA,EAA,EMA,EMAA etc. |

Coating Thickness | 8-45um |

Coating Average | ≤±5% |

Substrate Material | 35-350g/m2 Paper |

Max.Unwind Diameter | 1200mm |

Max.Rewind Diameter | 1200mm |

Tension Control | Full Automatic Constant Tension Control Of Unwinder,Rewinder,Closed-loop tension control |

Control Method | Human-Machine Interface,Extrusion thickness is automatically precision calculated by computer,whole machine linkage control |

Inverter | Imported AC Digital Vector Control Inverter |

Machine Dimension(L*W*H) | 22m*9.5-12m*4.5m |

5.Machine Part Photos:

1st Extruder & Sherman Corona

2nd Extruder

Unwinder

Rewinder And 3 Rollers Cooling System