With China's accession to WTO, more and more foreign companies have spotted the Chinese market, especially in the sector of plastic products which are widely used in the daily life. Foreign companies started to invest in China, and build production bases in China, to control product quality, increase productivity, increase profits through the “system of automated machinery and equipment” containing leading technologies, and win the market through timely services.

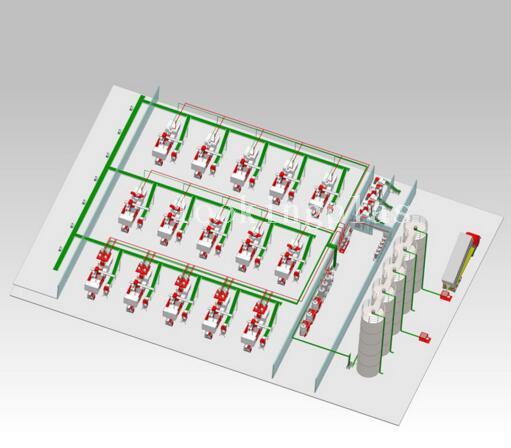

Therefore, in recent years, domestic and foreign manufacturers of plastic products have been continuously improving the production machinery and equipment, with a focus on the central automatic feeding system at injection molding workshops, which is due to the following features of this system:

Save labor costs and raw material costs, long service life (over 10 years);

Energy saving (saving electricity);

Centralized management of raw materials, to avoid wastes and pollutions;

Keep the factory environment clean, and maintain the ISO14000 Environmental Management System;

Isolate the main material feeder, thus reducing noise and stabilizing workers' moods;

Help maintain stable quality, improve values, and maintain the ISO9000 Quality Management System;

Help improve the company's image and win customers’ cooperation.

Therefore, this system is the inevitable trend in the development of plastic products manufacturers, as well as the R&D results of our company. Over the past more than 10 years, our company has been providing professional and scientific automation system engineering design based on professional theoretical design, and backed by the practical experience, having not only created practical values of machinery, but also injected beauty into the projects! The research results are not only the breakthroughs based on high-technologies, but also the new breakthroughs and new ideas achieved by integrating technology, production, and applications in life.