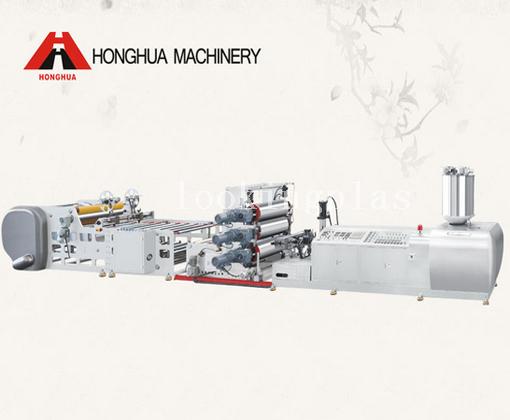

PRODUCT INTRODUCTION :

It is used for Produce plastic sheet of PP, PS, HIPS, PE etc. which can be used for produce plastic formed sheet, Stationery. Extrude Between By Down And Middle Roller Automatic sheet rewinder Main Technical Parameter Maximum output 400kg/h

INTRODUCTION

It is used for Produce plastic sheet of PP, PS, HIPS, PE etc. which can be used for produce plastic formed sheet, Stationery.

|  |  |

Extrude Between By Down And Middle Roller |

Automatic sheet rewinder |

|

Main Technical Parameter

| Maximum output | 400kg/h |

| Heating power of die head | 15kw |

| Diameter of screw | 100mm |

| Heating power of screen changer | 5kw |

| Thickness of die mouth | 0-3mm |

| Motor power of calendar | 3 x 2.2kw |

| Diameter of roller | 400mm |

| Motor power of rewinder | 2.2kw |

| Adjust distance of roller | 0-50mm |

| Air pressure | 0.6Mpa |

| Diameter ratio | 33:01:00 |

| Water consumption | 20m3/h |

| Width of die mouth | 850mm |

| Air consumption | 0.1m3/h |

| Face length of roller | 1000mm |

| Sheet thickness range | 0.15-2mm |

| Number of roller | 3个 |

| Width Maximum | 720mm |

| Motor power of extrude | 75kw |

| Heating power of drum | 22kw |

Main features

| The machine is a combination of extruder, calender, rewinder and electric control box etc. The barrel have advanced designed, lower the height and install Insulation components, Energy Recovery from the screw rotate and run back to dryer to save energy and improve the capacity The head is adopted hanger-type branch pipe decreasing-style construction, so the flow passage is convenient for solution to flow without stagnation and cooling inside roll and bring a perfect effect. The temperature of die head, mesh changer and the drum separately controlled. All drive system runs synchronously. |