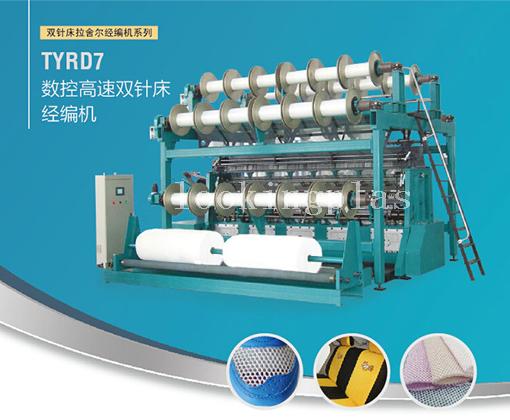

TYRD7 Digital high speed double needle bar raschel machine

APPLICATION

After cutting and finishing the fabric can be formed short plush which height is 1.5-6mm, or sandwich mesh spacer fabric which spacing is 3-12mm, its plush is fullness and soft. Wool yarn into a circle and not easily detached from the base fabric. The machine is widely used in car upholstery, sofa, simmons, cotton blanket, curtains and other household decorative fabrics, clothing fabrics and shoe fabrics.

CHARACTERISTIC

Used in all oil-immersed eccentric linkage mechanism or crank linkage, drive faster; fixed knockover comb bar, compact fabric. Increased grip stitch comb bar unloading device allows the stitch comb bar away from the work area to facilitate the operation when replacing the latch needle.

Electronic let-off, laser broken yarn automatic stop device etc. The high degree of automation to ensure high-speed operation of the machine and is easy to operate. The machine has 7 guide bars, and can be equipped with electronic jacquard, electronic take-up device, so the fabric of the machine is more able to meet the needs of customers.

MAIN TECHNICAL SPECIFATIONS

| Needle type | Latch needle |

| Gauges | E16, E18, E22 |

| Working width | 138" |

| Guide bar number | 7 |

| Double pile height | 3-12 mm |

| Main drive | Oil-immersed cam, Eccentric linkage |

|

| Speed | 600-800 rpm |

|

| Pattern drive | N-pattern drive, chain link or pattern disk

(Optional: Electronic Control) |

| Yarn let-off device | EBA Electronic yarn let-off |

| Fabric take-up | Take-up driven by change gears(Optional: Electronic take-up) |

| Batching device | Independent batching device |

| Main motor power | 5.5 kw |

SCHEME OF INSTALLATION