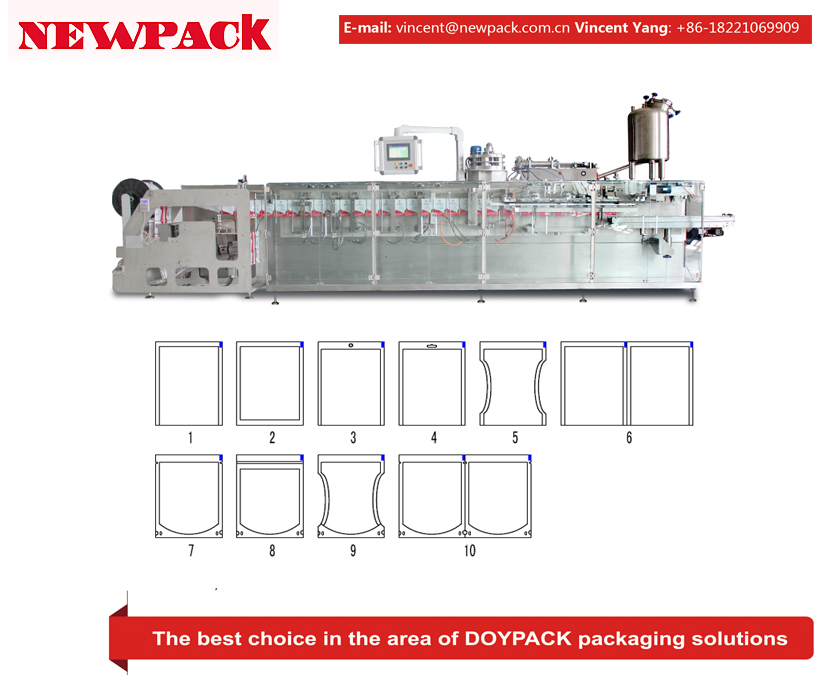

1.The improved equipment lager packaging: Packaging volume can reach to 2000 ml of adjustable. The biggest bag size up to 210×320×120. To solve the model 180 volume cannot meet the wide volume adjustment of the packing requirements.

2. High cost performance: Modular design, only need to configure the corresponding function module can complete the single bag or duplex the production requirements; The fastest speed packaging single bag up to 3600 pouch per hour, and double pouch up to 7200 pouch per hour。Only need to configure the corresponding function module can complete the single bag or double the production requirements of flat pouch, self-supporting pouch, hanging hole pouch, round pouch, special pouch, suction nozzle pouch, zipper pouch,and other types of pouch.

3. Wide range: Widely used in nuts, seasoning powder, tomato sauce, jam, chili sauce, juice, jelly, Soybean Milk, edible oil and so on。

4. Complete machine configuration: Using different manufacturing processes: stainless steel and carbon steel, stainless steel frame and part configuration, to meet different application requirements; To enhance the flexibility and economy of the machine.

Technical data | HMK2000 |

Simplex | Duplex | Pouch function |

Pouch format(W×H×G) | MIN.(mm) | 70×110×40 | 70+70×110×40 | Shape/hanging hole/Sachet/ Zipper/Spout/Doypack |

MAX(mm) | 210×320×120 | 105+105×225×70 |

Filling capacity | MAX(c.c) | 2000 | 200 |

Packaging capacity | MAX(ppm) | 60 | 120 |

Machine dimensions (mm: L×A×H) | 5480×1100×1400 |

Net weight | 4000Kg |

Applications