HaflonTM Halogen-free flame retardants

Used in high temp. Nylon、PA、PBT、PET

ADP-10

Product Description

ADP-10 is a halogen-free flame retardant based on organic phosphinates,white powder,called Aluminum Diethyl Phosphinate.The product is not hygroscopic and is insoluble in water and common organic solvents like acetone, dichloromethane, MEK, toluene and so on.

Benefits

Non-hygroscopic, not hydrolyzed and not precipitated

Suited as flame retardant for thermoplastics and thermosets

High efficiency due to its high phosphorus content

UL 94 V-0 rating down to 0.4 mm thickness

Suited for processing temperatures up to 350 °C

Suitable for both glass fiber reinforced and unreinforced grades

The flame retardant polyamide compounds exhibit very good physical and excellent electrical properties

Suitable for lead free soldering

Good colorability

Non-halogenated flame retardant with favorable environmental and health profile

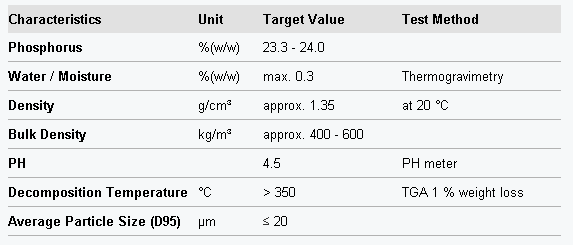

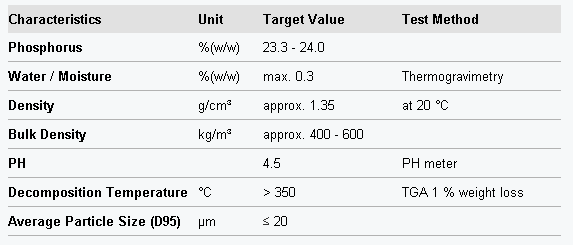

Specification and Technical Data

Applications

ADP-10 is suited as flame retardant for thermoplastics and thermosets. Due to its high phosphorus content the product is distinguished by a high efficiency.

ADP-10 can even be applied in high temperature polyamides because of its high temperature stability. It is suitable for both glass fibre reinforced and unreinforced grades. The flame retardant polyamide compounds exhibit very good physical and electrical properties.

In high temperature polyamides of PA 6T/66 type, a dosage of approx. 15 % (by wt.) ADP-10 is usually sufficient to obtain the UL 94 V-0 classification for electrical compounds (at 1.6 as well as 0.8 mm thicknesses). Subject to the polymer grade, processing conditions and glass fibre reinforcement the dosage of the flame retardant may vary.

Processing

Before incorporating ADP-10, it is important to predry the polymer as usual. If possible, the resulting moisture content should be below 0.1 % (by wt.) for high temperature polyamides, 0.05 % (by wt.) for PBT and 0.005% for PET. Predrying of ADP-10 is not necessary. However, predrying (e. g. 4h at 120 °C) is recommended, if even very low moisture contents must be avoided.

Wear and corrosion protected materials are recommended for compounding and injection-molding of ADP-10 in reinforced polyesters, high temperature polyamides, or aromatic polyamides.

The mixing and processing methods customary in powder processing of polymers can be used with ADP-10.

The optimum conditions for incorporating should be determined in each individual case. Care must be taken to ensure homogeneous dispersion of all components. The temperature of the polymer melt should not exceed 350 °C.

Packaging and Handling

Delivery form

White powder

Packaging

20 kg /bag, using paper bags with PE inner.The product should be stored in a dry place at room temperature.