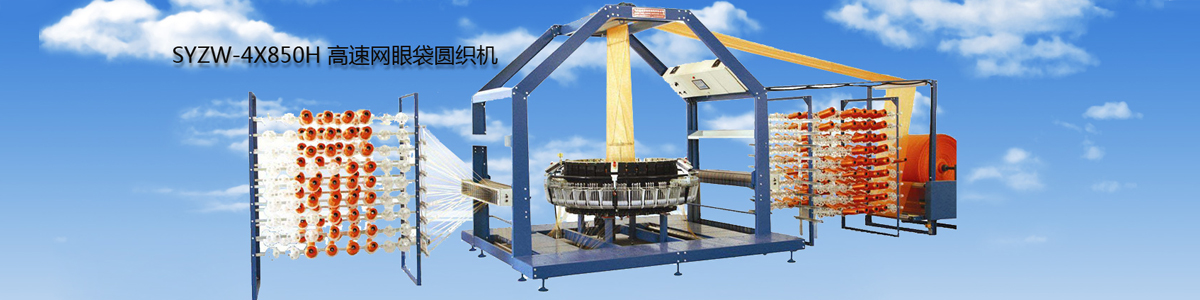

SYZW-4X850H High speed plastic mesh bag loom

Twenty yearns ago, we adopt the principle of leno fabric in weaving plastic yarn,as the first company in China which invent leno bag loom,we get tremendous success.

With the development of technology today,we present you the latest type of leno loom.As the new loom adopt advanced mechanical and electric technology,the new loom has following superiority:60% increase of speed,40% decrease of power consumption,greatly reduce the wearing out parts.With higher degree of automatic,the new loom is more convenient to operatie

1.The shuttle body is made of high-strength engineer plastics,the advanced and unique shuttle and shuttle rail ensure the shuttle running smoothly without shuttle coming -out . The rolling friction of the shuttle wheels make the lower power consumption and lower noice.

2.The electric control system adopts the centralized control of SCM,both loom rotary speed and take-up speed are controlled by inverter,the sensors send signal to the SCM system,and realize the synchronization weaving and fabric take-up. The weft density can be adjusted and conpensated automaticlly.The fabric output in meters is shown on the screen for each shift and accumulating to one day or one month.

3.The new winding system adopted constant swing tension device with two sensors to control the movement. To avoid stretch and shrink of the leno fabric,the swing -arm up and down with the fabric when machine running.This system make sure the tension of the fabric constant and winding the fabric smooth and in line.

Main technology parameter

| Item | SYZW-4X850H |

| Number of shuttles | 4 |

| Main speed | 100rpm (Max) |

| Folded width | 300-850mm |

| Weft density | 10-37 picks/10cm |

| Quantity of warps | 576 pcs Max. |

| Bobbin size | Φ38×230mm

|

| Max dia of weft bobbin | Φ105mm |

| Power of main motor | 3kw |

Power of winder motor

| 0.37kw |

| Overal size | 9.2×2.8×3.2m |

| Whole weight | 2500kg |

For constant improvement of design,some change may not be able to proior notice.