Characteristics and applications:

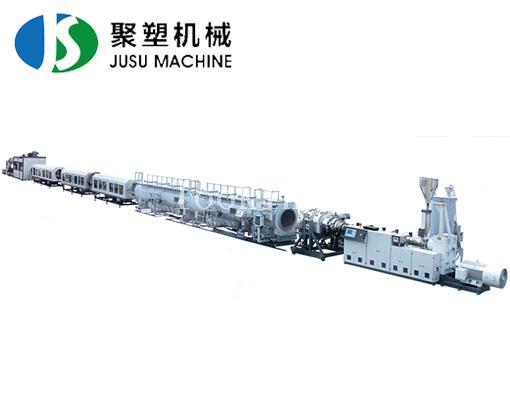

The production line is mainly used to manufacture for PE plastic pipe,and GF series tube auxiliary equipments production line can also be used to process other plastic.Extruder and GF series tube auxiliary equipments production line take the features of advantages,reliability & applicability together,and provide strong certification for high-quality plastic tube for customers.

This production line adopts high-efficiency single-screw extruder,equipped with extrusion mould,vacuum shaping tank,spray cooling tank,haul-off,planetary cutter and controlled by PLC micro-computer system.

Main Technical Parameter

Model | Structure | Pipe Range(mm) | Total Length(m) | Max.Output(kg/h) | Total power(kw) |

PE-32 | High-speed style | Φ16-Φ32 | 26 | 180 | 90 |

PE-32-S | High-speed style | 2-Φ16-Φ32 | 26 | 280 | 140 |

PE-63 | High-speed style | Φ16-Φ63 | 34 | 260 | 110 |

PE-110 | High-speed style | Φ20-Φ110 | 34 | 350 | 135 |

PE-160 | High-speed style | Φ50-Φ160 | 40 | 400 | 180 |

PE-250 | High-speed style | Φ75-Φ250 | 48 | 450 | 215 |

PE-450 | High-speed style | Φ160-Φ450 | 60 | 650 | 320 |

PE-630 | High-speed style | Φ315-Φ630 | 68 | 900 | 510 |

PE-800 | High-speed style | Φ450-Φ800 | 76 | 1000 | 630 |

PE-1000 | High-speed style | Φ500-Φ1000 | 78 | 1100 | 720 |

PE-1200 | High-speed style | Φ630-Φ1200 | 80 | 1300 | 800 |

PE-1600 | High-speed style | Φ900-Φ1600 | 88 | 1500 | 950 |

PE-2000 | High-speed style | Φ1400-Φ2000 | 90 | 1800 | 1200 |