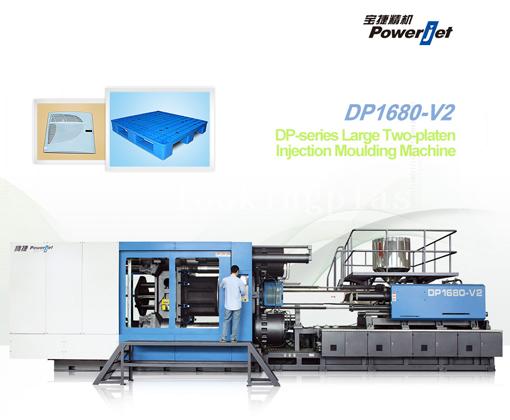

eatures:

1.With short length and compact structure, the whole machine occupies less floor space.

2.Dispense with mould adjustment, it is more convenient and faster to change the mould.

3.With large opening stroke and colossal spaces between bars.

4.With elegant appearance.

Clamping System:

| 1.Direct-press type of clamping structure with high-precision pressure pick-up ensures accurate clamping forces.

2.Four bars are exerted equal force and have short stress segment; it brings the clamping units good rigidity and long life expectancy.

3.Finite-elements-analyzed and optimized mould has good rigidity and small deformation.

4.Oblique cylinder with rapid mould movement.

5.Dispense with mould adjustment, it reduces machine wear.

6.With multi-ways of hydraulic ejector system.

7.Automatic centralized lubrication system. |

Injection System:

1.With double injection cylinders, it makes injection movement more stable.

2.6 staged injection, 5 staged pressures maintaining, 3 staged pressures and speed control in pre-plasticization.

3.2 ways of initial control for pressure maintaining (location, time).

4.With anti cold burden start function.

5.We use large-toque oil hydraulic motor as pre-plasticization device.

6.Screw rotary speed detection devices.

7.Differential injection function increases the injection speed.

Hydraulic System:

1.With multi variable pumps & closed-loop control, the system is more energy saving.

2.Unattached high pressure oil pump can create clamping forces of high pressured rapidly.

3.Imported hydraulic parts and seal components.

4.Bypath oil filter of high-precision.

Electric control system:

1.Dedicated controller of Techmation from Taiwan.

2.With colored large LCD screen, the computer supports for multi-languages.

3.With automatic protection function, the screen prolongs its life expectancy at a large margin.

4.With high-performance, reliable, stable imported electric components.

5.It is realizable to control the proportion of back pressure by computer, which makes the plastics melting more stable and precise. (Optional function)

Safety System:

1.With anti-pinch injury function, it is speed- adjustable to open or close the electric security gate.

2.Nozzle Injection protective cover can prevent plastic material ejected.

3.Double safety protection systems of hydraulic and electric interlock.

4.With safety tread inside and outside of mould, it protects personal safety.

Parameter:

Remarks:According to upgrading of machine, we will change techical parameters, configuration of some parts and service’s items without further notice.

Platen Dimensions:

Service and support:

.12 months free of charge warranty service on complete machine and parts ( wearing parts not included ) and 5 years for the 3 mould platens

.Provide consultant on product and technology before sales

.Provide special engineering design according to customer requirements

.Assist customer to design factory layout, water and electricity facilities layout

.Test running & training free of charge

.Maintenance service in 24 hours

.Product upgrading and reconstructing services

.Training on product maintenance

.Value added service on upgrading plastic parts quality

.Other services

Note:

.Theory injection capacity = screw diameter2×π/4×screw travel

.Actual injection capacity is the maximal weight of polystyrene ( PS ) raw material injected to air.

.When UPVC, PC, PMMA, PA and other engineering plastic material are used, please let us know. When you need modifying parameters and functions of the machine, please let us know also.

.According to demand of machine upgrade, we will change technical parameters, configuration of some parts and service’s items without prior notice.

.Photos are for reference only. If there is any difference with actual products purchased, the real products are final.

.In normal condition six months warrantee for barrel & screw; But using caustic or any recycling material is not guaranteed.

Video link in the production process:http://v.youku.com/v_show/id_XNTY5MDE5NzE2.html