Technical parameters: |

Cavity: | 1 | Stretching stroke: | 190mm | Rated power: | 32KW |

Really use power: | 22KW | Max volume: | 5L | Max container diameter: | 170mm |

Max container height: | 330mm | Max neck diameter: | 150mm | Theoretical output: | 600p/h |

Machine dimension: | 3300*1700*1800 | Machine weight: | 2000KG |

|

|

Purpose/application field:

ST series of the most stable two step automatic stretch blow molding machine (re heating), including a cavity to the eight chamber model, can blow 20ml-20L bottle.

The blowing machines can PET PP or other products made of plastic material, suitable for high yield, high quality requirements of pure water bottles, mineral water bottles ,beverage bottles, carbonated soda bottles heat, cans and bottles, edible oil bottle, cosmetics bottles, infusion bottles PP.

Advantages:

High automation: PLC control stable production

Through the automatic rotation of the tube and the chain in the oven operztion,the strong penetration of infrared heating, uniform heating perfect cooling effect.

The oven has a flexible adjustment function, for different tubes, adjustable lamp and reflector reflection radian.

Each machine part of the automatic device to protect the operation of the safety procedures to prevent a sudden failure of a program.

Adopt servo drive to ensure non-pollution and low noise

Air blowing and other actions are divided into three parts, which effectively resolve the problems arising from air pressure and movement

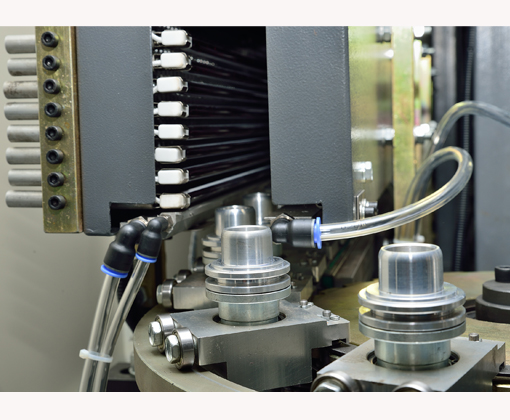

With the injection molding machine principle of hyperbolic arm linkage lock, the lock force is large and the stability is good

The hand is one, simple and convenient

No pollution, less than 0.2 percent