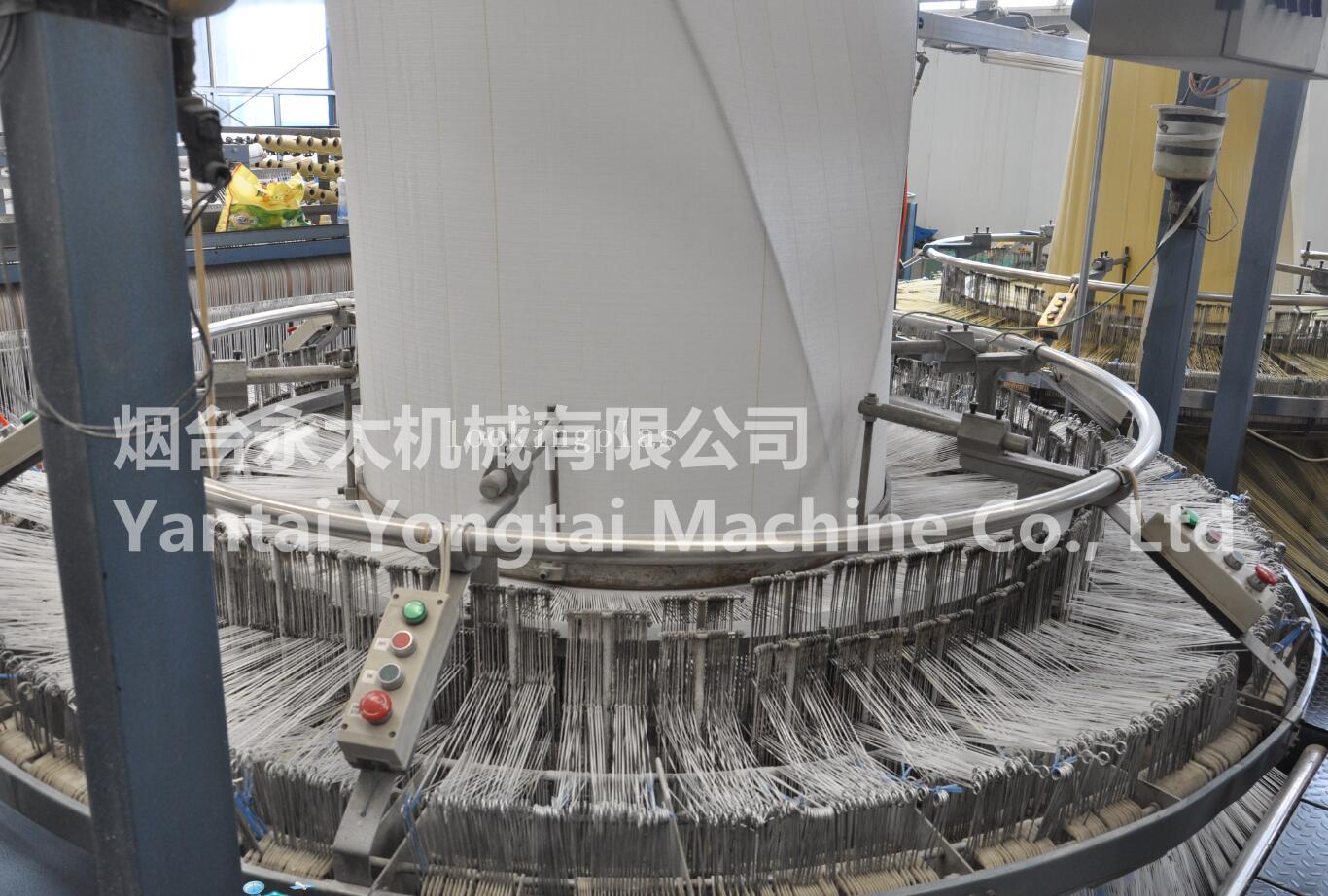

Type: SBY-1400*6E

Revolutions: 10~85rpm Variable frequency control

Power of main motor: 5.5kW

Main speeding down motor):

(taper gear wheel speed reducers connected straightly with the electric machine)

Shuttles: 6

Track width : 125mm

(The face of the track is plated with hard chromium.)

Folder: 950—1400mm

(Most adjustable scope1000-1350mm)

Number of warp: Max 1920 pieces

Density of weft: 32—64 pcs/100mm

(Through changing gears to change density of weft)

Theoretical capacity: 48—96m/h

Warp diameter: Maxφ120mm

Weft diameter: Max 105mm

Involution electrical machine: 15kg.cm

Involution width: Max 1400mm

Involution diameter: Max φ1100mm

Manner of statistics length:(Count tool of machinery three shifts)

Specification of the shuttles: φ38*230 or φ38*270

Type of yarn plate: φ38

Warp broken control:

(When warp breaks It can stop voluntarily)

Weft broken control: (Automatic control system of weft-broken and weft-end)

Lubricating style: The cam has forced circulating lubrication with oil injection.(Lubricating oil deals with precipitation and filter of oil box)(The lubricating style of shuttle is through oil cup dripping down)

Oil route protection): It can stop automatically if the oil route has jam.

Outline size: (L) 16m*(W) 3.3m*(H) 4.25m

Features of the machine:

1).The small-cam designing makes the inertia small to start-up,

and with high speed.

2). The track with swallow-tailed flume can prevent shuttle out.

3).The dynamotor type weft detector is sensitive and reliable, it can’t be influenced by dust. It can stop automatically after weft end. And it can ensure the quality of products.

4).The cam is lubricated circulated by force. This can promote the efficiency of the machine. It has warning device of oil route jam, this can avoid abnormal wearing and tearing of the parts.

5).The cloth roller turbine speed reducer adopts flexible connection , this can prolong the life of the speed reducer.

6). The fold scope is large, with wide range of uses. One machine can be used in several way.

7).The structure of the equipment is reliable and simple, it’s reliable to operate. The parts those are easy to be broken are few .They are convenient to be maintened. And the revolving cost is not high.

8).The electrical system is controlled by PLC.