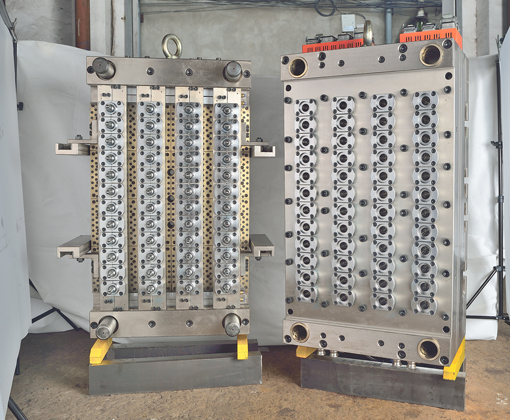

Billet mould configuration:

The whole modular part;

The overall structure of the mould is compact and precise, (push plate, slide block, hot runner material adopt P20), the template material is S50C module;

Template to eliminate internal stress being complete, stay around 500 ℃ under vacuum for 36 hours, gradually cooled after finishing, the long-term use of template deformation caused by using unstable factors such as;

The mould frame is made up of all the templates, which guarantee the concentricity of the forming hole and the guide column, and the overall mold height is high.

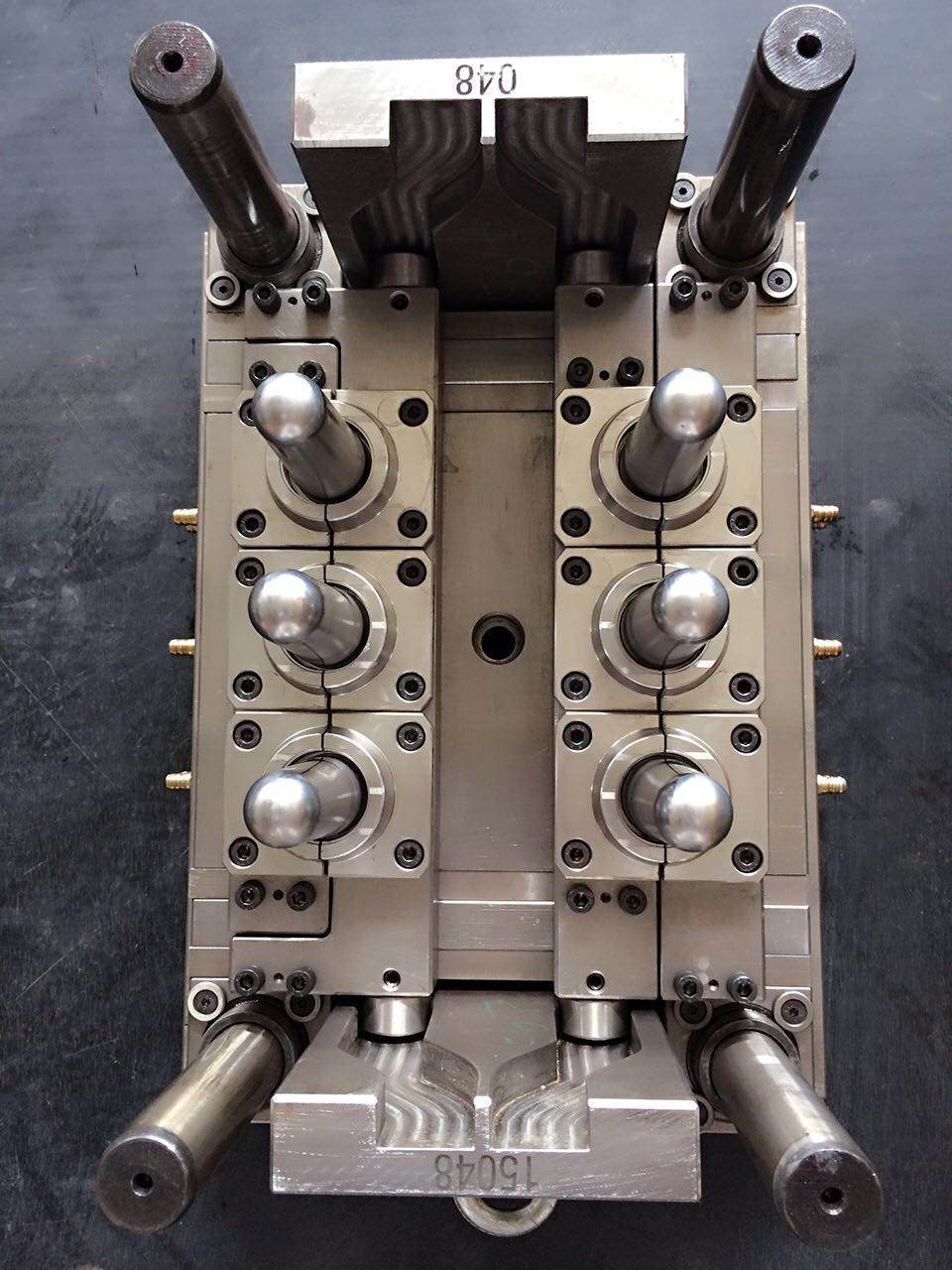

Fostered the slider mould clamping adopts mechanical clamping, HUSKY material for import S136 high strength anti-corrosion steel, reliable structure, mold the whole process (slider, pushing board, top step coordinate), all sliding parts contact advanced ion nitriding processing, partial surface hardness can reach HRC48-52, small friction coefficient, wear resistance;

Slide block (adopt the HUSKY mechanical design structure);

The material of forming parts (mold, cavity, thread mouth) are all imported S136 high strength corrosion resistant steel, HRC 46-48.

Using the HUSKY double cone reset principle, the process of processing manufacturing accuracy can not produce the change factor such as eccentric, etc.

Using the small giant equipment of ningxia, the size is accurate and accurate

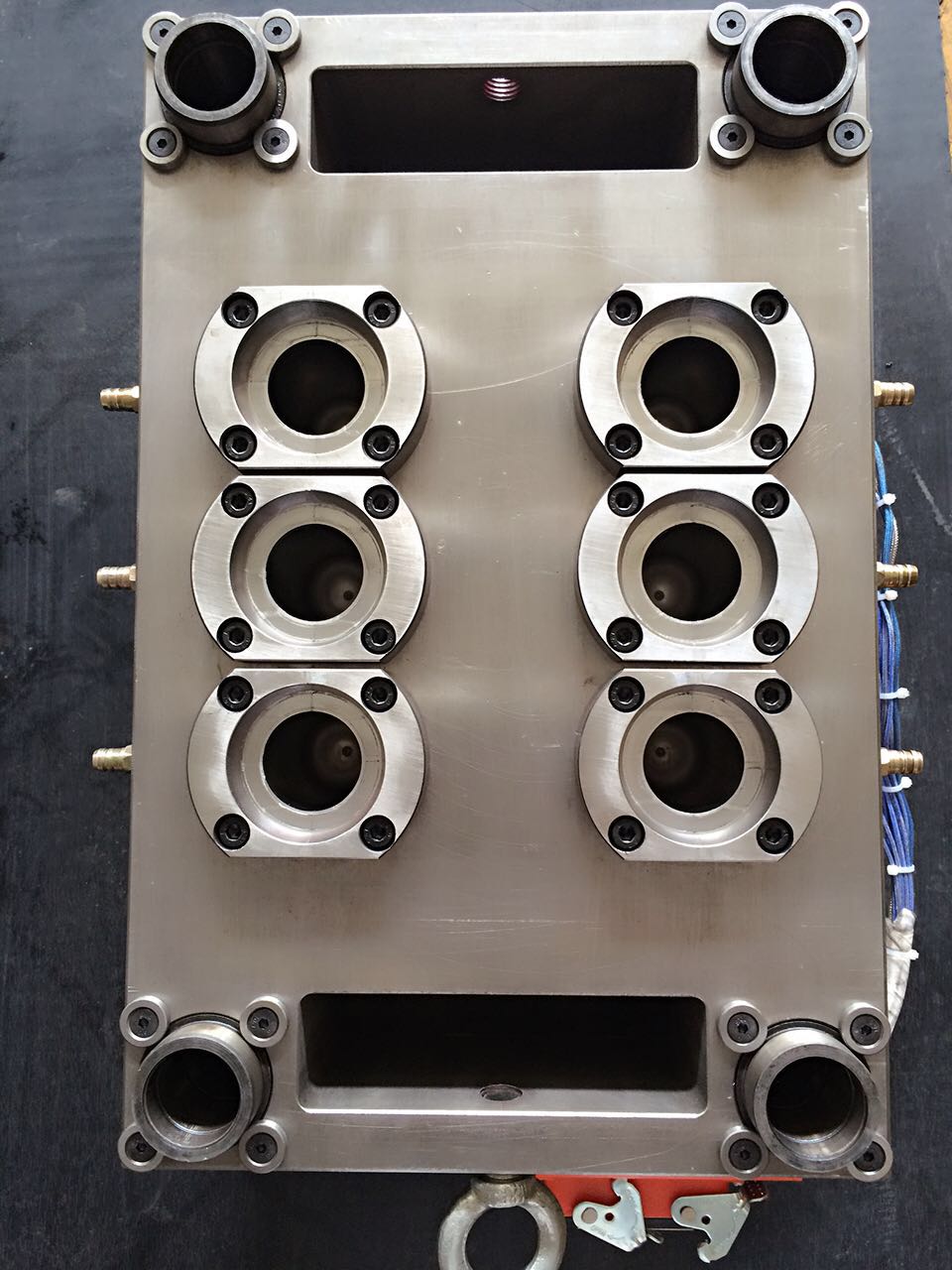

The section of the hot runner;

The hot runner parts are made of SKH61 high strength resistant materials, HRC is greater than 40.

The main channel heating tube adopts the guangdong dongguan cheng brand heating bar, which is buried in the pipe and not easily damaged.

Hot lips are heated by ROTFIL in Italy or HOTSET in Germany, and quality assurance is reliable (not damaged in three years, according to the unit);

Nesta structure is used in hot mouth being straight feed type, flow channel is smooth, cooperate with needle valve parts is smooth, high precision hole (within 0.004 mm), the surface hardness between HRC52, hot mouth is made of beryllium copper, HRC is greater than 35.

The high strength QBE2 beryllium copper insert is used in the front end of the heat mouth (injection mouth).

The hot tip of the mouth (injection-mouth) is used by American dupont;

The valve pin is the top bar in dalian, the material is SKH61, hrc52-60 surface with special treatment, high accuracy and wear and tear.

Low sliding imported wear ring piston and cylinder, service life is long, the piston material use imported S136, after heat treatment, precision machining, adopt imported seal, the sealing material for high temperature resistant polyethylene fluorine tetrachloroethylene;

Low the sprue hole for high precision deep hole drilling processing, port of high precision, smooth surface, smooth, small resistance, will not lead to a plastic molecules, carbide mold product streamline light clear and bright;

Low hot runner is made of high quality imported S136, rough machining after 550 ℃ to 250 ℃ under the vacuum condition, the stability of 48 hours, eliminate the mold used for heating may lead to deformation, material simulation using the default process, the overall performance is good;

Low overall heat mould part of the cooling performance is good, in the process of normal injection, mold outside body temperature is very low (about 40 and 55 ℃), elimination of injection molding machine set template will not lead to the thermal deformation, by hot runner heating expansion damage such as adverse factors such as mould precision machine;