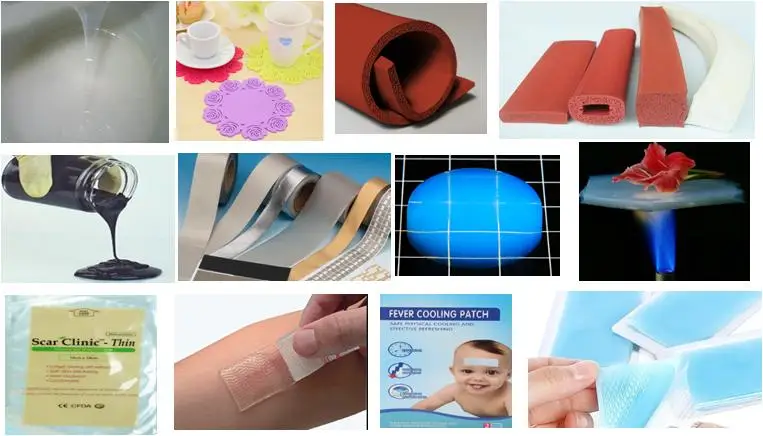

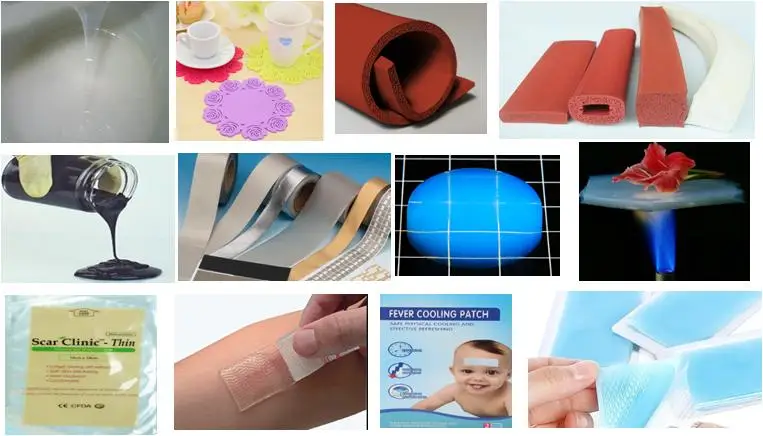

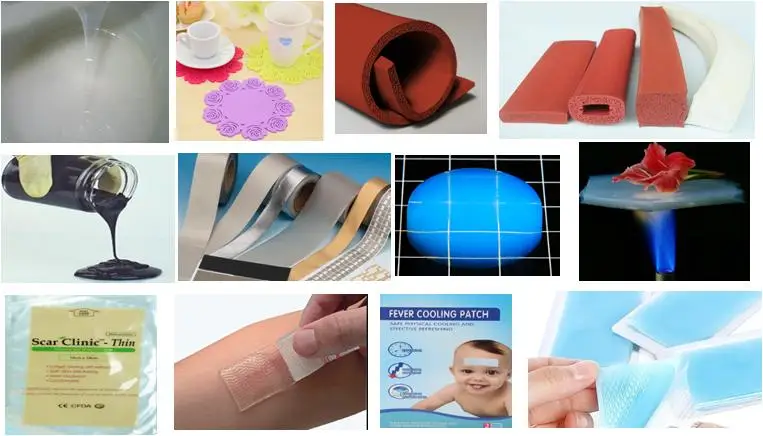

Application Range

It’s applicable to make various liquid or semisolid state materials, such as liquid silicone, liquid foam silicone, semisolid silicone, conductive fabric, conductive paste, scar treatment strips, antipyretic paste, hydrogel, gel, silica based aerogel, seal product, buffer product, LCD light shielding, foam, heat insulation aerogel film, ETC.

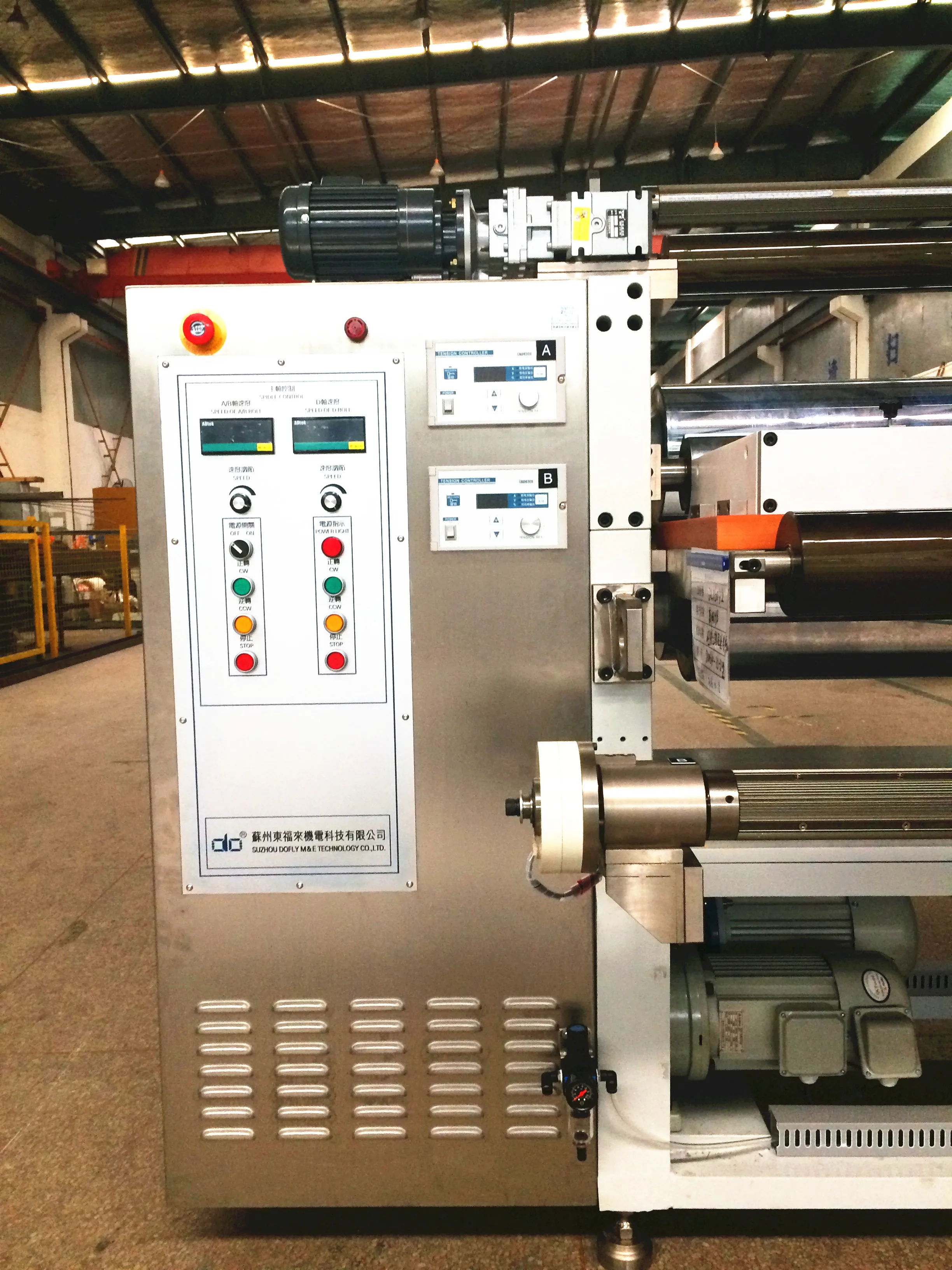

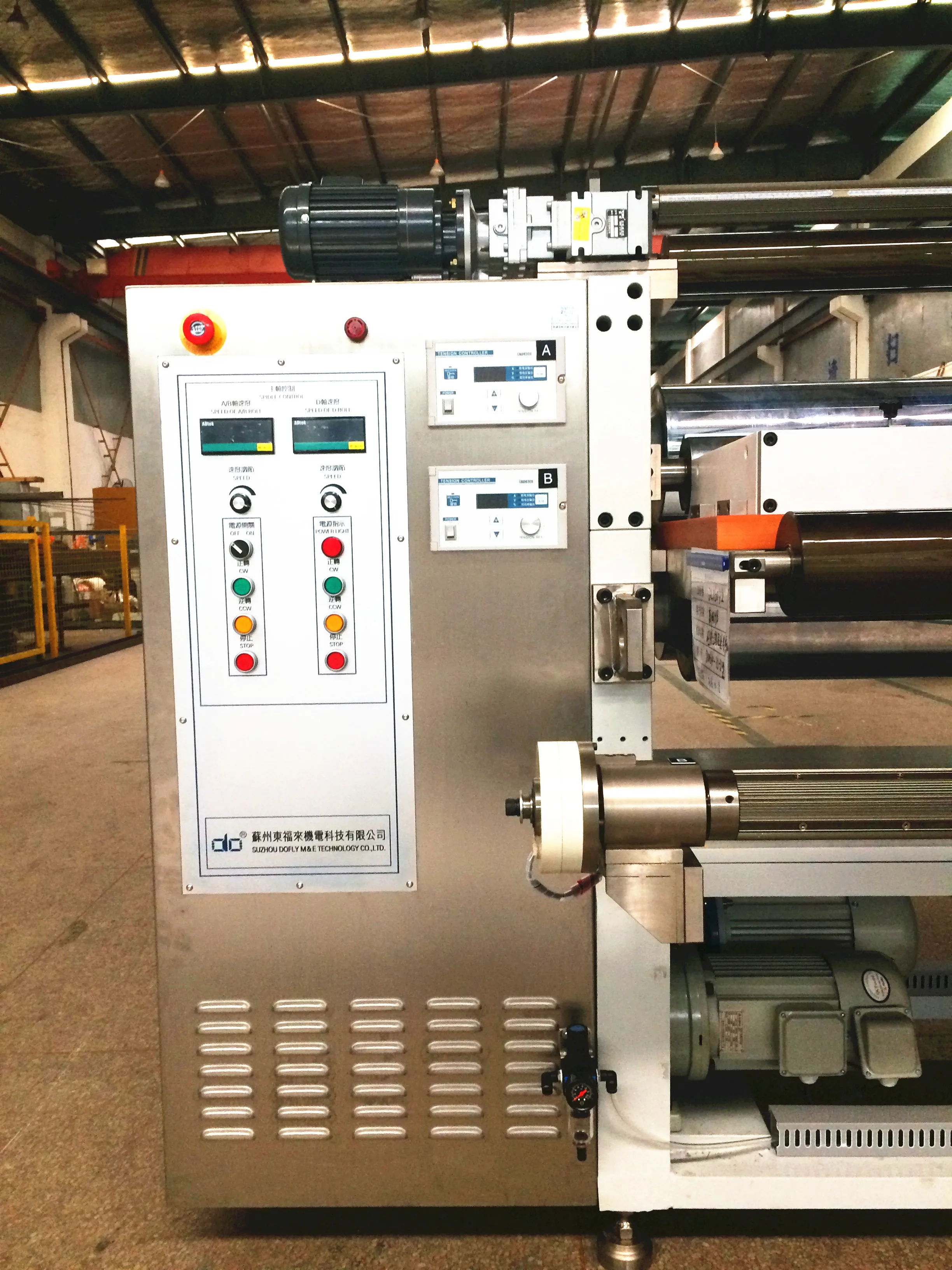

Picture Details

All our machines are made by customized, If you need more products information, like technology parameter or vedio and so on, Please contact to our sales by hereinafter contact information.

Machine Advantage: Customized, Multifunction, Automation, High quality, High precision

Features:

1, For the inputting unit, It is integrated into the overall machine, so, it’s easy operating and can save occupying space.

2, For tension control, it is automatically controlled by magnetic powder brake and tension controller, so the labor is saved.

3, For the main power driving system, The AC special motor matched with frequency convertor as the machine’s power transmission can individually control each roller speed, and efficiently process different thickness products and ensure the products’ quality, In comparision to general producing craft, This machine can save electricity 50%-90%.

4, For the roller adjusting device, the gear reducer motor and precise screw adjusting gap device have been adopted, which can adjust the roller gap both sides at one time or individually adjust each side gap.

5, For the roller gap detection, the roll gap is detected by high quality grating scale, display the gap distance in real time, the detection precision is +/- 0.005mm.

6, For the automation meter counter, It can be set two segment length, and can precisely calculate and control the producing length.

7, For the roller’s surface hardness, It can be HRC 68-70 depends on customer’s requirement.

8, PLC control are optional depends on customer’s requirement

9, High quality and famous brand’s electrical parts, which also can be appointed by customer.

Core Advantage:

According to customers requirement, After many years of research, Dofly had successfully developed this coating and calendering machine for processing liquid or semisolid state silicone and aquogel and medical material, in order to solve the issues of wide range of viscosity or bulbbling or other difficulty to make, we had provided the final solution for our customers.

Machine Specification:

We had just listed a part of the model we made before, any special function you need to learn, please help contact with our sales. Thanks!

Model | DCM500-3S

Series | DCM550-3S

Series | DCM630-3S

Series | DCM650-3S

Series | DCM750-3S

Series | If can be

customized |

Roller width(mm) | 500 | 550 | 630 | 650 | 750 | Yes |

Max. outputing width(mm) | 400 | 450 | 500 | 550 | 650 |

|

Max. unwinding diameter(mm) | 600 | 600 | 600 | 600 | 600 | Yes |

Unwinding shaft diameter | 3" | 3" | 3" | 3" | 3" | Yes |

Max. roller gap(mm) | 6 | 6 | 6 | 6 | 6 | Yes |

Max. working speed | 15m/min | 15m/min | 15m/min | 15m/min | 15m/min | Yes |

Outputing tolerance(mm) | ±0.015 | ±0.015 | ±0.015 | ±0.015 | ±0.015 | Yes |

Total power (Kw/h) | 9 | 9 | 10 | 10 | 11 | Yes |

Machine size (mm3) | 1600*1700*2000 | 1600*1700*2000 | 1700*1800*2000 | 1700*1800*2000 | 1700*1800*2000 | Yes |

Power Voltage | 380V | 380V | 380V | 380V | 380V | Yes |

Certificated by | CE | CE | CE | CE | CE | Yes |

If oven can be equipped | Yes | Yes | Yes | Yes | Yes | Yes |

Quality assurance:

1, The warranty period is 12 months, a set of tools and necessary spare parts for quick-wear components can be provided for free charge.

2, Dofly provide free usage trainning for customers before shipping.

3, Our customer service is standby at any time. once we get customer’s complaint, the solution will be worked out in 24 hours.

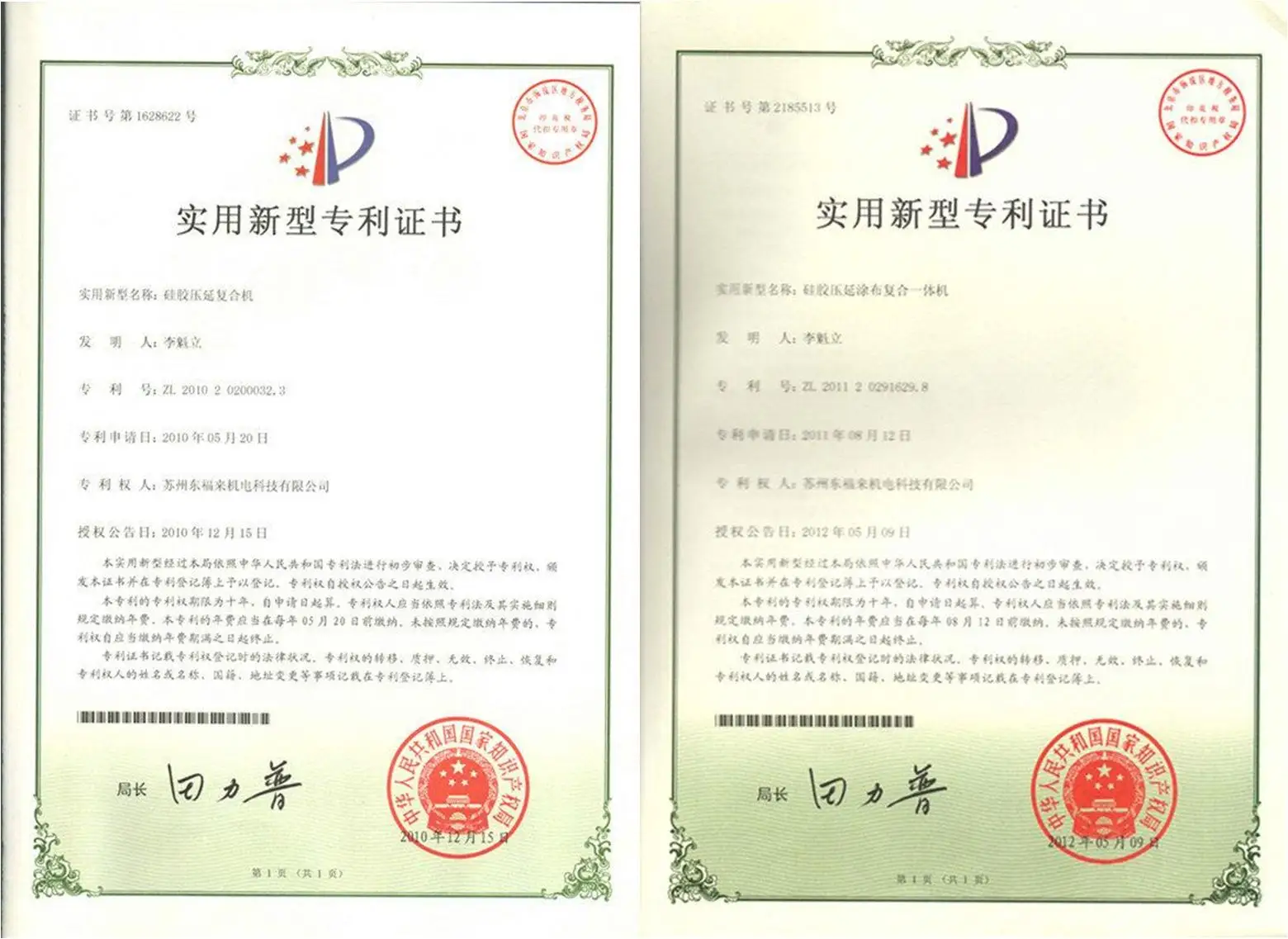

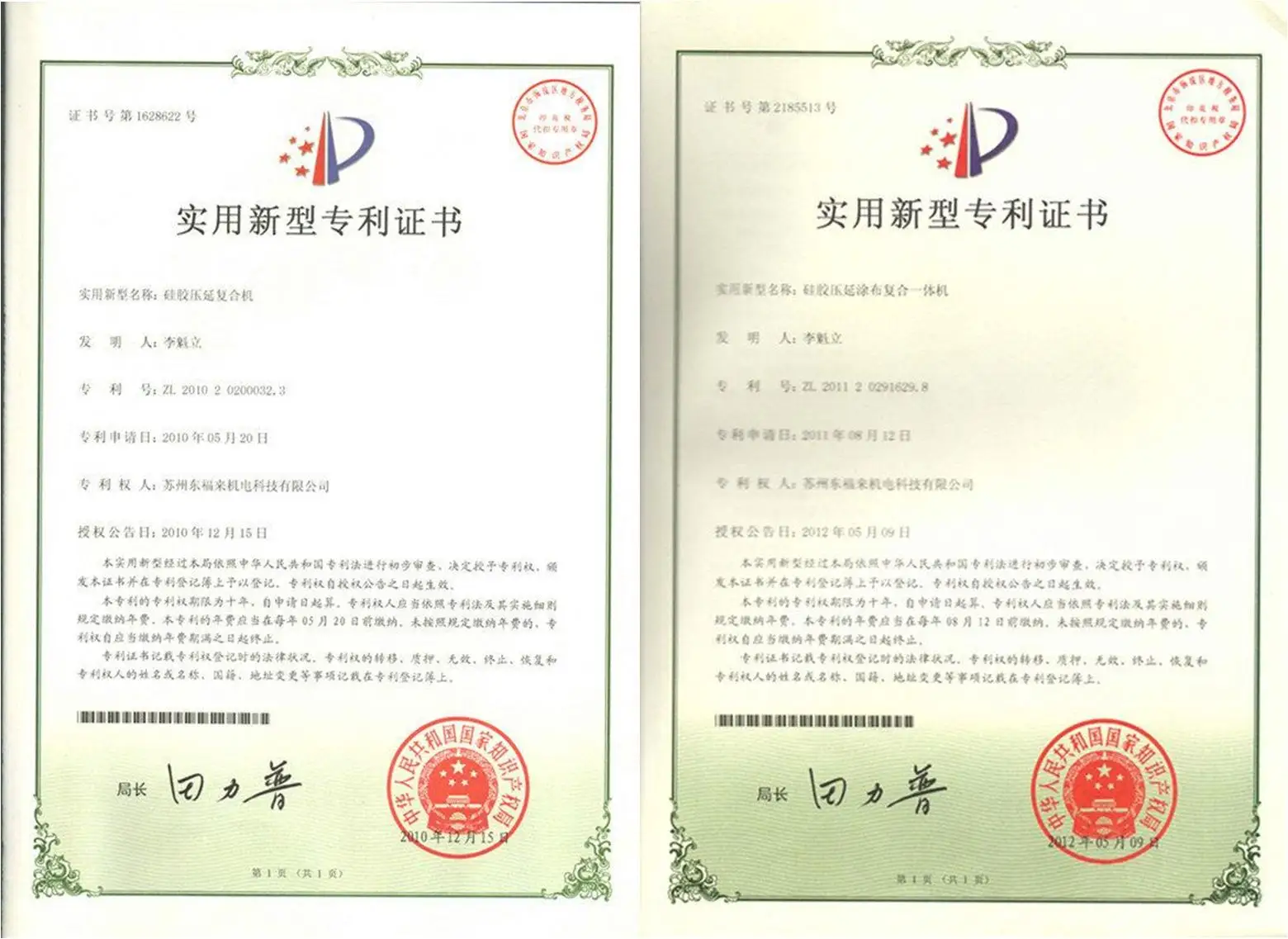

Machine Certifications

Most of our products had obtained national patent, and had been certificated by CE, we also can apply for other related certification according to customer’s requirement.

Packaging & Shipping

PACKAGE:

Fumigated and seaworthy wooden case marked necessary security identifier.

DELIVERY TIME:

1,The leadtime is around 45days.

2,Shipping from SHA port or by customer requirement.

Our Service

1, Dofly has an excellent R&D center, we have been providing good solution for our customer to solve the issues of craft and production quality and efficiency, ETC.

2, Dofly provides the pilot run test for verifying the craft and equipment for free.

3, Dofly can make a promise for customer's final products.

4, The warranty period is 12 months, a set of tools and necessary spare parts for quick-wear components can be provided for free charge.

5, Dofly provide free usage trainning for customers before shipping.

6, Our engineers are available to service machinery overseas.

7, Our customer service is standby at any time. once we get customer’s complaint, the solution will be worked out in 24 hours.

Our Customer

Our Customers are all around the world, we have been providing the value-added solution and equipment for the new materials’ enterprise of the globe, with our advanced technology and good service, we have got the trust and praise from our customers.

Company Information

SuZhou Dofly M&E Technology Co., Ltd. is specialized in the craft R&D and equipment R&D for functional advanced materials, provides the whole process craft and customized equipment from experimental stage to bulk production for cumstomers.

Since our company established, We have been upheld the conception of Innovation, High Quality, Customer Service, Sustainability.

In order to meet the developing requirements of the national new materials industry, Dofly has already taken the R&D of new manufacturing craft and equipment, which is suitable for new materials industrialization, as the priority of our developing strategy. So, we focus on that, and provide the whole solution for the new materials'customers. Our equipment are calendering or roller press machine, coating machine, slitting and rewinding machine and ETC.

The applicable functional materials include special metal material, advanced polymer material, new inorganic nonmetal material, high performance composite material, leading new material, ETC.

Our machines are widely used into many industrial fields such as electron, communication, new energy, armarium, auto, aviation, aerospace, ETC.