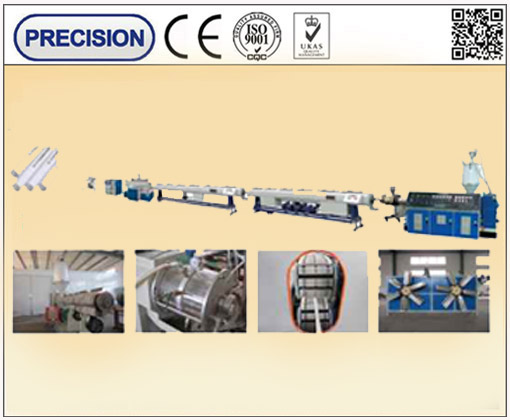

Description of PERT Floor Heating Pipe Production Line:

Application:

Widely used in producing PE-RT floor heating pipes.

Characteristics of the equipment:

1. High speed extruder adopts notched barrel with water forced cooling transportation zone and shielded screw with special mixing structure, ensuring high speed and efficient extrusion.

2. Specially structured spiral accumulator type die head surmounts stress orientation of polymer chain during forming pipe and achieve a constant pressure pipe extrusion, making that good physical and chemical properties of PE-RT material be copied into the pipe; meanwhile the stability extrusion pressure is a strong guarantee for high-speed manufacturing.

3. Vacuum calibrating mandrel adopts multi-sheet water immersion calibrating mandrel designed by our company, realized the cooling calibrating evenly and effectively for plastic pipe, ensuring high speed production of the pipe.

Main Technical Parameters:

Model | Pipe range | Extruder | Output | Extruding speed | Total power | Overall dimension |

PERT-63 | 20-63 | SJ-65/33 | 80-120 | 1-15 | 90 | 30×1.8×2.5 |

PERT-160 | 75-160 | SJ-75/33 | 260-300 | 0.4-1.5 | 120 | 32×2×2.5 |

Specification and standard equipment are subject to change without notification.