|

Type of extruder

|

L/D

|

Screw speed

rpm (MAX)

|

Main motor power Kw

|

Production capacity Kg/h

|

|

SHJ-20

|

32-52

|

500

|

4

|

0.5-15

|

|

SHJ-36

|

500

|

11-22

|

20-80

|

|

SHJ-50

|

500

|

37-45

|

80-160

|

|

SHJ-60

|

300/400/500

|

45-55

|

100-250

|

|

SHJ-65A

|

400/500

|

55-75

|

150-300

|

|

SHJ-65B

|

600

|

75-90

|

250-500

|

|

SHJ-65C/D

|

600

|

90-110

|

350-700

|

|

SHJ-75A

|

400/500

|

90-110

|

400-800

|

|

SHJ-75B

|

600

|

110-132

|

650-1000

|

|

SHJ-75C/D

|

600

|

132-160

|

700-1500

|

|

SJH-95A

|

500

|

240-280

|

700-1200

|

|

SHJ-95B

|

600

|

240-315

|

1000-2000

|

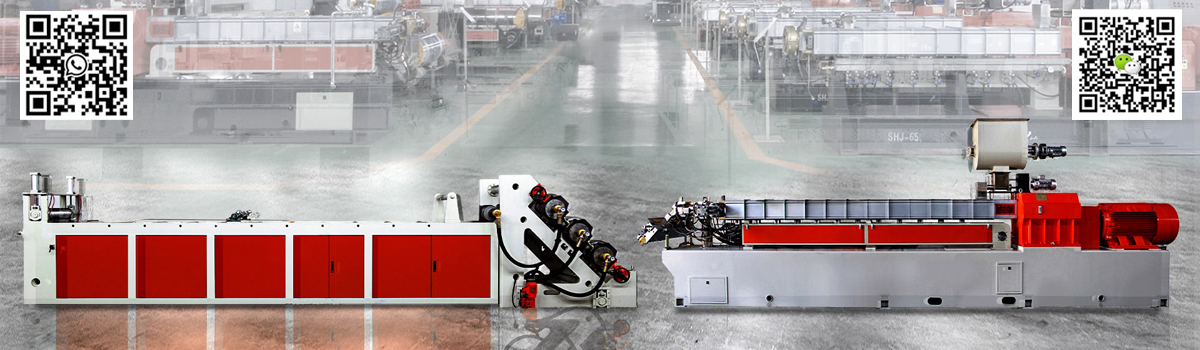

Technical Features:

SHJ series extruder consists of driving part, processing part and electrically controlled parts.

Driving part consists of Gear-box and main motor. According to the customers’ request, there is four types can be chosen: Normal type, High speed gear-box type, High-speed, High-torque gear-box type and imported gear-box. If the customer make sure which kind of the gear-box will be adopted, then the speed of main motor is clear. Also, the main motor has A/C or D/C type available for choosing.

The gear-box adopts parallel triaxial structure. It deviced oil pressure meter, oil level/oil temperature device( can see the oil level and oil temperature.), but low oil level alarm device and filter blocked alarm system and so on is available for selection fitting.

Processing part consists of barrel, screw parts and two pieces of co-rotating screw. There are closing barrel, Feeding barrel, venting barrel, sideway feeding barrel, liquid feeding barrel. The screw parts array can be adjusted according to processing technology. It can realize transmitting, plastizing, compounding, shearing, venting and dehumidifing. Granule, powder, liquid can be fed by main feeder, side feeder or liquid injecting unit, or multi-way loss-in-weight feeds system.

Speed control: Using the advanced imported digital frequency converter or DC speed Regulator to ensure speed be controlled best.

Temperature control: Using dual-pass brainpower type, imported metes.

Low voltage parts: Using SIMENS,SCHNEIDER brand, insure the parameters more safety And long life.

Cooling system: Using Italy’s electromagnetic valve(CEME or ACL) Insuring safety and long life.

Advanced melting temperature and melting pressure display monitor, showing the Flowing material state.

All the signal line, small power line adopts Aero-Plug, it convenient for installation avoids make wrong

direction or wrong position.

Suitable For:

Polymer blending, filling and modification ;

Engineering polymer, reinforced plastic with fiber

General and fiber masterbatch

Functional granule

Special material, powder coating granule

Variety ofcable granule

Reactive extrusion, devolatilization for postprocessing

Aluminum-plastic plate, panel, wood-plastic granulation, plastic films, sheets and plates.