Purpose/application field:

The machine is made of PET,PP or other plastic materials, applicable for pure water bottles, mineral water bottles, beverage bottles, carbon acid beverage bottles, hot canned bottles, editable oil bottles, make-up bottles and medical injection PP bottles that all have a high production volume and requirement for quality.

Machine features:

1. Highly automatic:PLC-control stable production.

2. Make sure strong-penetration even infrared heating through automatically rotating the pipe base and the chain in the oven(perfect cooling effect)

3. The oven has flexible adjustment function,and the light tube and the reflection plate can be adjusted to suit different pipe bases.

4.The self-lock device operation procedure of each mechanical part can prevent the abrupt breakdown of each of procedures.

5.The servo drive can make sure free pollution and low noise.

6.Dividing the air pressure frame inside the machine between the blowing and other actions into three parts can effectively solve the problems in air pressure blowing and other actions.

7.using the locking mode with double crane-arm connecting rod as used in plastic injection machine can make sure a big lock power and perfect stability.

8.Operation mode:integrated with manual and automatic operations, making them simple and convenient.

9.The secure, reliable and unique valve design can make it more convenient for the operators to get familiar with the air pressure structure of the equiment.

10. Low cost ,high efficiency,operability and maintainability.

11. No pollution on the bottle body and low scrap rate<0.2%.

Full Automatic Blow Molding Machine Technical parameters:

| ITEM | UNIT | ST-2L/2F | ST-2L/4F | ST-2L/6F |

PRODUCT SYSTEM | Number of cavity | / | 2 | 4 | 6 |

Clamping force | Kg | 16000 | 48000 | 60000 |

Clamping stroke | mm | 130 | 130 | 130 |

Max.container volume | L | 2 | 2 | 2 |

Max.container diameter | mm | 105 | 105 | 105 |

Max.neck diameter | mm | 38 | 38 | 38 |

Max.container height | mm | 330 | 330 | 330 |

(max.volum)output | Pcs/h | 1700-2000 | 3500-4000 | 4800-5500 |

ELECTRICAL SYSTEM | Total power | kw | 28 | 56 | 72 |

Actual heating power | kw | 21 | 30 | 39 |

Air system | Operation pressure | Kg/ cm2 | 7 | 7 | 7 |

Blowing pressure | Mpa | 3.5 | 3.5 | 3.5 |

High pressure air consuming | L/min | 1600 | 2400 | 4000 |

Low pressure air consuming | L/min | 1200 | 1600 | 2000 |

MACHINE | Main Machine dimension | mm | 1500*1900*2100 | 4300*2100*2300 | 5300*2100*2300 |

Main Machine weight | kg | 2000 | 3500 | 4500 |

Auto loader dimension | mm | 2.3*1.4*2.9 | 2.3*1.4*2.9 | 2.3*1.4*2.9 |

Auto loader weight | kg | 250 | 250 | 250 |

NOTE:Plesse tell me what plastic product you want to produce and I will help you choose the best model for your needs. We believe that our competitive prices high quality and excellent service will bring us both benefits. Choose us-choose the best!

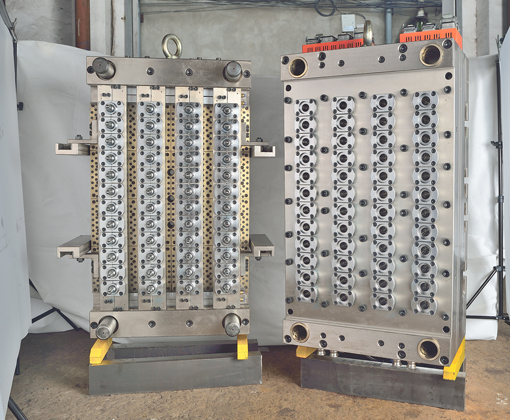

Machine details: