Single Screw Extruder

High output

ZXSJ Series of efficient single screw extruders designed by PARTNER plastic machinery co.,ltd. It adopts Germany and Italy advanced technology. Screw adopts the latest Barrier design plus mixing system.

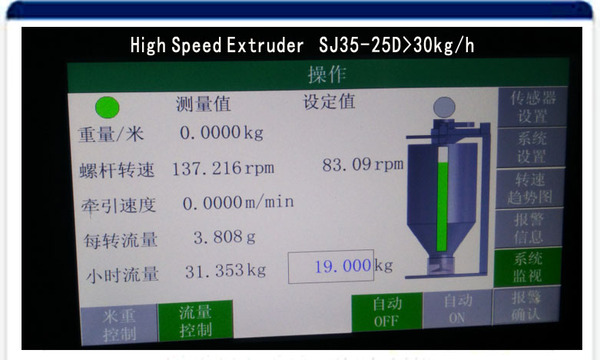

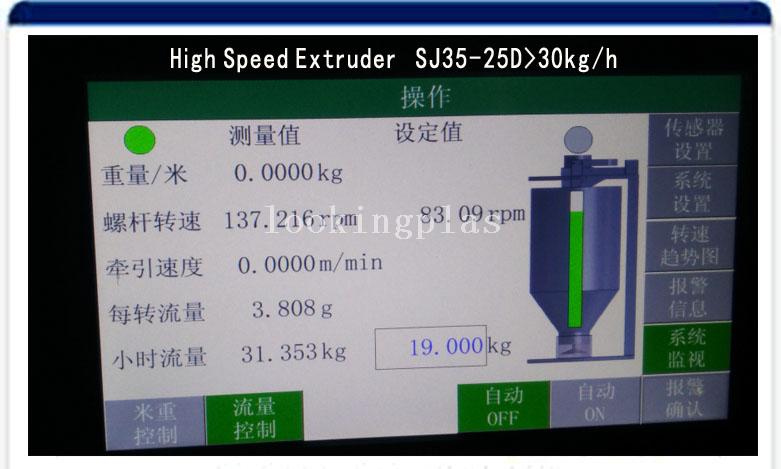

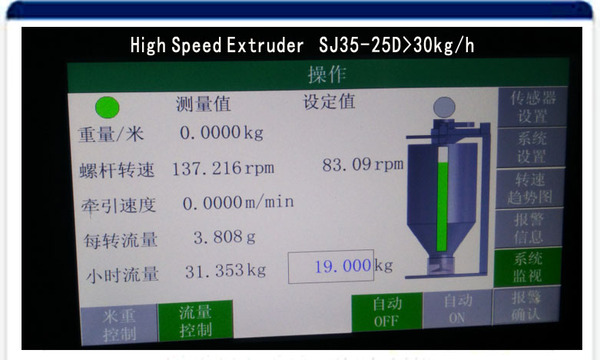

New extruder design capacity: 30-25D, extrusion capacity up to 32 kg / h

Single Screw Extruder is one of the core operations in polymer processing and is also a key component in many other processing operations. The foremost goal of a machine extrusion process is to build pressure in a polymer melt so that it can be extruded through a die or injected into a mold. Most machines are plasticating:

they bring in solids in pellet or powder form and melt them as well as building pressure.

Our single screw extrusion machines excel in producing sheet, pellets, pipes, GRP, and profiles of wood and natural fiber plastic composites.

Our company PTSJ Series of Single Screw Extruder Systems gives all the advantages for productive operation.

•Standard AC/DC motor & drive package.

•Reduction gear reducer with heavy duty integral roller trust bearing for extended life.

•Large cast-in water jacket in feed throat for efficient cooling.

•Quality barrel & Screw for long life.

•2-position Screen Changer.

•Standard RKC/OMRON Temperature controller or optional Siemens PLC control.

•Melt temperature and melt pressure indication.

•Extruders available from 25mm through 150mm. (According to the customer's request)

Main Technical Parameter |

Model | Screw Diameter (mm) | L/D | Heating& Cooling zone | Total installed power (kw) | Max. Output (15~22Mpa) (kg/h) |

ZX30-25D | 30 | 1”25 | 3/3 | 7.5 | 28-32 |

PT30-25 | 30 | 1”25 | 3/3 | 2.5 | 6-8 |

PT35-30 | 35 | 1”30 | 3/3 | 7.5 | 10-15 |

PT50-33 | 50 | 1:33 | 4/4 | 37 | 100-120 |

PT65-33 | 65 | 1:33 | 4/4 | 55 | 180-210 |

PT75-33 | 75 | 1:33 | 4/4 | 90 | 300-350 |

PT80-33 | 80 | 1:33 | 5/5 | 110 | 350-410 |

PT90-33 | 90 | 1:33 | 5/5 | 132 | 450-500 |

PT120-33 | 120 | 1:33 | 6/6 | 250 | 850-900 |

PT150-33 | 150 | 1:33 | 4/4 | 400 | 1300-1400 |

DS30-25 | 30 | 1:25 | 2/2 | 5 | 2 |

DS40-25 | 40 | 1:25 | 3/3 | 15 | 4 |

DS45-25 | 45 | 1:25 | 3/3 | 24 | 25 |

DS45-30 | 45 | 1:30 | 4/4 | 25 | 40 |

DS45-34 | 45 | 1:34 | 4/4 | 30 | 80 |

DS50-32 | 50 | 1:32 | 4/4 | 44 | 80 |

DS65-25 | 65 | 1:25 | 4/4 | 46 | 80 |

DS65-28 | 65 | 1:28 | 4/4 | 53 | 100 |

DS65-30 | 65 | 1:30 | 4/4 | 62 | 120 |

DS65-34 | 65 | 1:34 | 4/4 | 100 | 290 |

DS65-35 | 65 | 1:35 | 4/4 | 116 | 340 |

DS80-34 | 80 | 1:34 | 5/5 | 150 | 420 |

DS80-35 | 80 | 1:35 | 5/5 | 172 | 540 |

DS100-34 | 100 | 1:34 | 5/5 | 238 | 760 |

DS150-34 | 150 | 1:34 | 6/6 | 460 | 1250 |

DS150-35 | 150 | 1:35 | 8/8 | 258 | 600 |

DS170-35 | 170 | 1:35 | 8/8 | 353 | 700 |