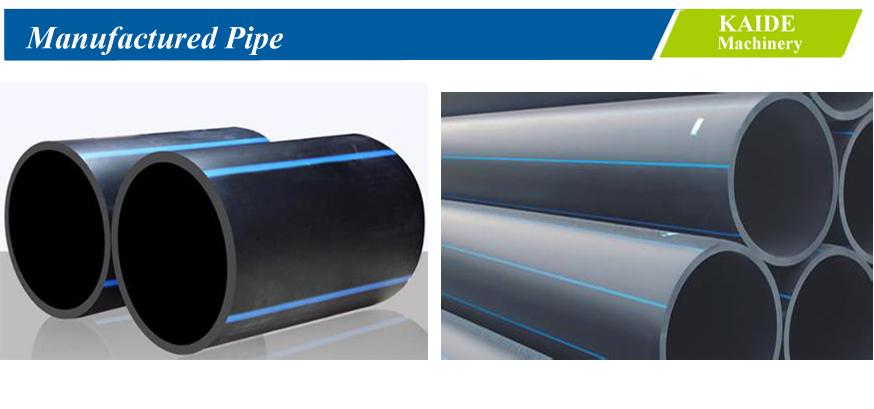

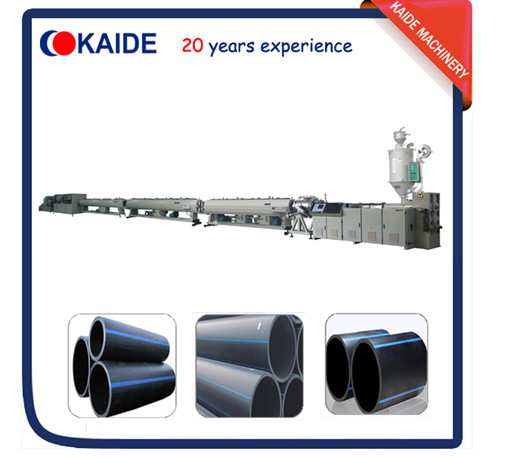

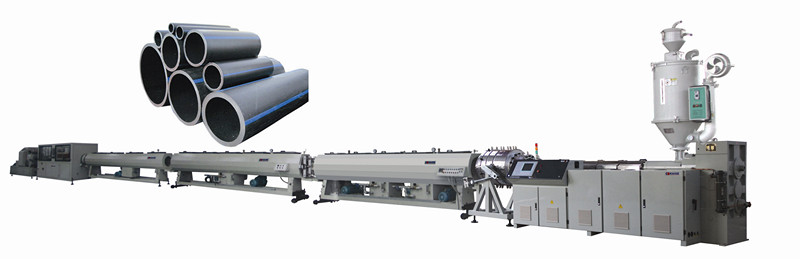

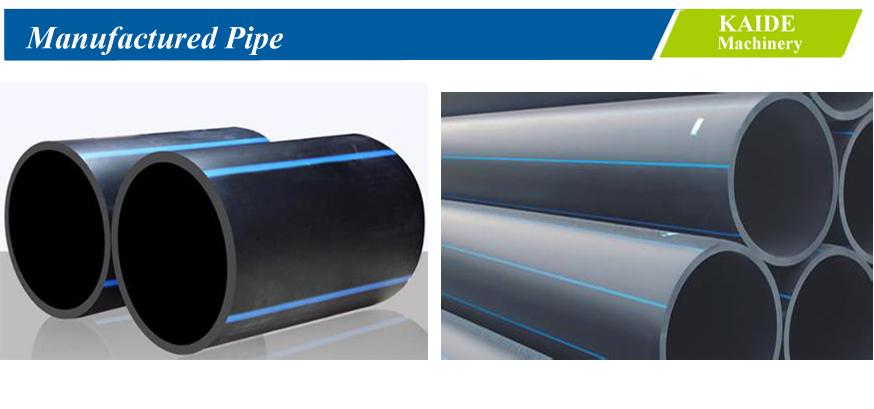

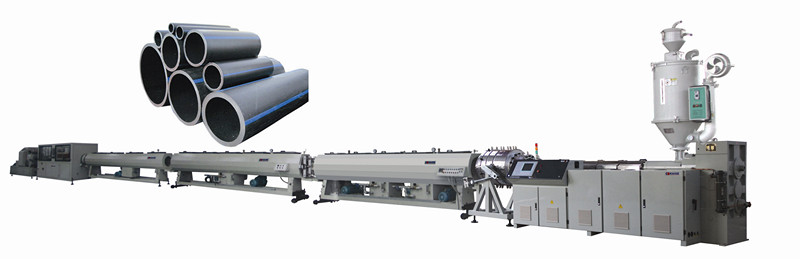

Large Diameter HDPE Pipe Making Machine/ HDPE Large Diameter Pipe Production Line

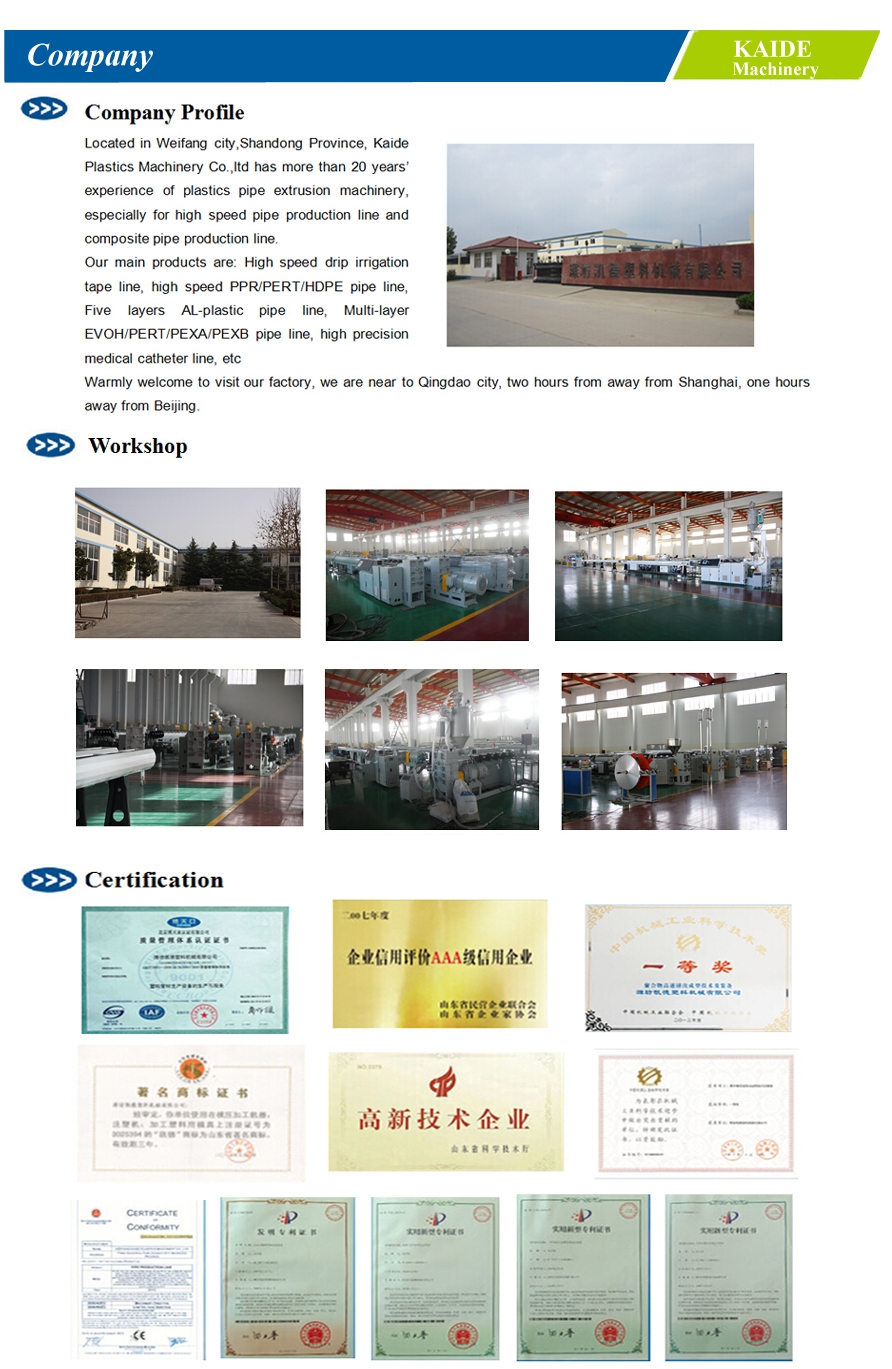

KAIDE factory has focused on plastic pipe extrusion technology for more than 20 years, especially for high speed pipe line and multi-layer pipe line.

For small diameter HDPE pipe from 20mm-63mm, the production speed can reach to 40-50m/min, in order to increase the production efficiency, reduce production cost, such as labor, electric and water consumption etc.

Features of Pipe Machine:

◆ High efficient five-section type screw, ensuring the stability and plasticizing quality of pipe extrusion.

◆ Spiral structure die head to ensure stability of high speed extrusion and produced pipe quality.

◆ Gravimetric material feeding system is to control material feeding according to pipe parameter & line production speed, to get high qualified pipe with constant weight per meter. It’s also have other benefits, such as shortening start-up time, saving raw material, simplifying operation.

◆ SIMENS programmable PLC control with big color touch screen. Having multi-point close-loop control and synchronous system, which ensure the easy and reliable operation of the line.

Technical Data:

Line Model | Screw Diameter | L/D | Pipe Size | Speed | Nominal Power |

HDPE-60 | Ф60mm | 36:1 | Ф20-63mm | 35m/min | 118KW |

HDPE-75 | Ф75mm | 36:1 | Ф20-63mm | 50m/min | 161KW |

HDPE-160 | Ф80mm | 33:1 | Ф75-160mm | 1-10m/min | 145KW |

HDPE-315 | Ф75mm | 36:1 | Ф110-315mm | 0.8-8m/min | 186KW |

HDPE-450 | Ф75mm | 36:1 | Ф200-450mm | 0.2-2m/min | 250KW |

HDPE-630 | Ф90mm | 36:1 | Ф315-630mm | 0.2-1m/min | 442KW |